Parallel Twin vs. V twin

Motorcycle engines come in equal variety, if not more fantastic, than automobile engines. Because of their limited space, engineers had to get creative to create the most compact engine possible, which is why we have so many options.

A four-cylinder inline engine is standard on large sports bikes since they have lots of space. An engine shaped like a V is fitted into an upright tourer bike's wide, tall frame. As no other engine would fit, scooters have a tiny one-cylinder engine.

As the name implies, a V-twin engine drove Honda's Africa Twin for a long time. What does it mean that the new one has a parallel twin, and what are the differences?

There will be reasons for and against, just like every versus. Let's review the advantages and disadvantages of each. It would help if you first ascertained the identities of both engines.

The V-twin is a two-cylinder, V-shaped engine. The mounting orientation can be longitudinal or transverse, depending on the bike's dimensions and intended use. A straight-twin engine, which has its cylinders arranged one behind the other in a line, is also known as a parallel twin.

The packaging of the parallel twin is its primary benefit. The V-twin engine is tiny, but it gains length when a primary drive and alternator are added to either end. Since the V-twin doesn't save any space in any case, the parallel-twin may easily compete with it in that area.

There is plenty of room behind the cylinders for engine accessories. This is because the exhaust pipe and rear cylinder do not occupy space at the back of the engine compartment. This allows the engine to move slightly forward towards the front wheel.

It's true that parallel twins typically need a balancer, but it's not a huge deal. Most balanced V-twins use twin balancing shafts or offset crankpins with a 90-degree V-angle, which could be more dependable. Their piston-shaking force is significantly greater than the parallel twin's since their displacement is often more significant.

The bike's exhaust makes a syncopated sound similar to a V-twin. This is due to the Africa Twin's parallel-twin engine, which has two crankpins positioned at 270 degrees.

Some people think this setup enhances traction. Some people believe this setup improves traction. Honda came up with a brilliant idea, changing one of its iconic models without sacrificing its conventional features.

Regarding the sound, that depends on personal taste. While the noise produced by the parallel twin is different from that of the V-twin, it is still tolerable. It's not as noteworthy or exceptional, but it's also not a deal-breaker. Some people prefer the exhaust noise of the parallel twin, but nothing can replace the incredible V-twin rumble.

Why the Harley-Davidson Motorcycle Evolution V twin Engine

Since producing its first motorbike in 1903, Harley-Davidson has advanced significantly.

The Evolution engine is a V-twin engine that Harley has produced and used for various models since 1984. The term "Evolution" refers to the redesign of the Harley engine. It is believed that the EVO engine helped prevent Harley-Davidson from going bankrupt.

The Evolution V-twin engine from Harley is a favorite among motorcycle enthusiasts, being one of their numerous V-twin designs. Exploring the Factors Behind the Popularity of the Harley-Davidson Evolution V-Twin Engine

Strength and Efficiency:

The Evolution engine, which took over from the outdated Shovelhead in 1984, introduced a range of improvements. The engine's displacement ranged from 883cc to 1,450cc, depending on the model, and it offered greater torque and horsepower than its predecessor. The V-twin design gives strong low-end power, perfect for relaxed rides and the distinctive Harley-Davidson experience.

Dependability and Longevity:

The Evolution engine had better reliability and fewer oil leaks. This was because of its improved combustion chamber design, better cooling, and enhanced oil circulation. The upgrades improved the engine's lifespan and reputation as a reliable workhorse on the road. The sturdy build also contributed to its enhanced performance.

Distinctive Sound and Style:

The performance of the Harley-Davidson brand is well-known, but so is its unique look and sound. The Evolution V-twin engine primarily produces the distinctive rumble that devotees have grown to love.

The loud exhaust noises made by the V twin engine are now strongly associated with Harley-Davidson motorcycles. These noises are distinctive and powerful. They are a result of the engine's firing pattern.

The Evolution engine has a classic design with chrome covers and visible pushrods. This design perfectly embodies the iconic Harley-Davidson look. Riders around the globe love this look.

Versatility and Customization:

The Evolution engine's adaptability and customizability are other factors that make it appealing. The engine is used in various Harley-Davidson models such as the Dyna, Softail, and Sportster series. This provides riders with a range of options to choose from based on their preferences. Riders can select a model that best suits their needs and desires.

In addition, a massive aftermarket for Harley-Davidson motorcycles offers enthusiasts many personalization and customization possibilities. The Evolution engine is popular. Many aftermarket parts and accessories are available for riders. They can customize their bikes for performance and looks.

How To Build a V Twin Gasoline Motorcycle Engine

On the engine forum in December 2020, I discovered a Harley-Davidson Panhead engine manufactured more than a century ago. The engine has a cylinder diameter of 16.7 mm and a stroke of 21 mm.

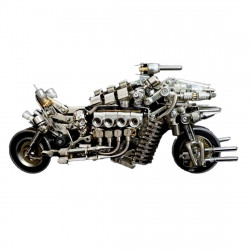

I chose to build my own little V2 engine model based on this engine as I was so drawn to it when I first saw it. I'm fond of engines and have quite a collection. They are so much fun while they are working.

Condition. I looked up material on Google and YouTube to preserve the simulation level and maintain the appearance. Because the machine is too ancient, I didn't even look at the actual engine. A few collectors may own it, and obtaining it is too challenging.

January 2020 was when I began developing the idea. This is challenging. The only engine information I have access to is from the current data.

I decided to utilize a rocker arm design with a standard OHV structure, which differs from the Panhead engine design. Yes, I find it simple to process, and I'm excited about how it will shorten my production cycle.

Every part of the engine will be CNC-made. It has an exquisite, moody aspect.

Since I enjoy collecting it, I won't be able to tolerate it in the future since oxidation will turn it dark. To keep it bright, I'll use an anodized cylinder surface. The rocker cover will also be chrome-plated, improving my spirits due to its beautiful appearance.

I had to finish my production during my free time as an engineer, so it took a long time. Finally, seven months later, it was finished. I attempted to start, but it was unsuccessful.

I discovered that the angle was incorrect when I inspected the camshaft. Because I had designed engines before, I assumed the two cylinders' camshaft angles were equivalent. Next, I simulated the 3D plan and estimated that I need to make adjustments. I also need to consider the angle of the ejector rod tilt.

I was going to give one of the cylinders a try. I withdrew the spark plug from the cylinder with the incorrect cam to avoid adding resistance to the cylinder that was ready to run.

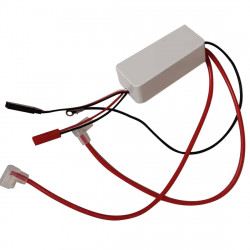

I tested a Hall igniter that I had welded. He was successful. The sound of the engine is intriguing and lovely.

After rebuilding the cam, I contacted my good friend and asked him to manufacture a new one. Yes, he used a cutting machine.

I began assembling the new cam. I double-checked the ignition timing for both cylinders. I realized he would need two igniters.

He would also need two Hall triggers. This was necessary if the trigger magnet was placed on the flywheel of the crankshaft. After a successful start, I will place him on the completed distributor.

Amazing! It got going. I'll optimize it to almost perfection next time.

This is a fantastic V2 engine that I'm proud to have in my collection, and I'm delighted to share the construction plan with you. When you see this engine, you'll notice it has a more than a century long history.