What is a Steam Engine?

A steam engine is a type of heat engine that uses steam as its working fluid to accomplish mechanical work. The steam engine pushes a piston back and forth inside a cylinder using the force created by steam pressure.

A connecting rod and flywheel can convert this pushing effort into rotational force for work. The steam turbine is not typically referred to as a "steam engine," only the reciprocating engines previously mentioned.

The working fluid and combustion products are separated in steam engines, which are classified as external combustion engines. The Rankine cycle is the ideal thermodynamic cycle that is utilized to examine this process.

The phrase "steam engine" can be used to describe either the entire steam plant (including boilers, etc.), as in railway steam locomotives and portable engines, or just the piston or turbine mechanism, as in beam engines and stationary steam engines.

Thomas Savery is credited with creating the first commercially used steam-powered device, a steam pump that used steam pressure acting directly on the water, even though steam-driven devices were known as early as the aeolipile in the first century AD. A few additional uses were documented in the 16th and 17th centuries.

Who Invented the Steam Engine?

Thomas Newcomen created the first commercially viable engine in 1712 that could supply a machine with constant power.

By transporting spent steam to a different vessel for condensation, James Watt made a crucial advancement that significantly increased the amount of labor produced per unit of fuel used.

The factories of the Industrial Revolution were powered by stationary steam engines by the 19th century. On paddle steamers, steam engines took the place of sails, and on railroads, steam locomotives ran.

Until the early 20th century, when improvements in the design of electric motors and internal combustion engines led to the gradual replacement of steam engines in commercial usage, reciprocating piston-type steam engines dominated the power landscape.

Because of their greater efficiency, faster working speed, and lower cost, steam turbines have supplanted reciprocating engines in the production of electricity.

How Does a Steam Engine Work?

A portion of the heat energy is transformed into work in a steam engine when hot steam, often from a boiler, expands under pressure.

For optimal engine efficiency, the steam can be condensed at relatively low temperature and pressure in a separate device called a condenser, or the remaining heat can be let out.

Because the steam expands inside the engine, it must pass through a wide temperature range in order to operate efficiently.

Using a low condenser temperature and a high boiler pressure ensures the most efficient performance, or the most production of work relative to the heat supplied.

As the steam travels from the boiler to the engine, it may pass through a superheater to receive additional heating. A collection of parallel pipes with their surfaces exposed to the hot gases in the boiler furnace is a typical superheater.

It is possible to heat the steam above the temperature at which boiling water produces it by using superheaters.

A valve mechanism allows steam under pressure to enter the cylinder of a reciprocating engine, which is a piston and cylinder type of steam engine.

In order to create rotary motion, the piston, which is often attached to a flywheel's crank, is pushed by the expanding steam. Steam is fed to either side of the piston in the double-acting engine alternately from the boiler.

A compound engine uses two or more cylinders of increasing size for greater expansion of the steam and higher efficiency than a simple steam engine, which uses only one cylinder. The first and smallest piston is powered by the first high-pressure steam, while the second is powered by the lower-pressure steam that is exhausted from the first.

A rotor of a steam turbine rotates at high speeds as a result of steam being released by nozzles at a high velocity and then passing through a number of stationary and moving blades.

Compared to reciprocating steam engines, steam turbines are more compact and often allow for higher temperatures and larger expansion ratios. The turbine is a ubiquitous device that uses steam to produce massive amounts of electric power.

Parts of Steam Engine

- Firebox: This is where the fuel is burned to create heat.

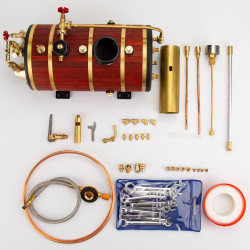

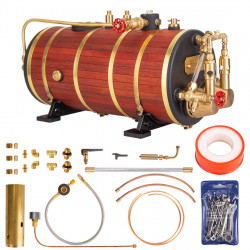

- Boiler: Lindy's boiler is a fire tube. In the boiler, hot gases generated in the firebox are drawn via a rack of tubes. To create steam, the tubes heat the surrounding water. The steam dome on top of the boiler is where the steam gathers.

- Steam Dome: The whistle, safety valve, and regulator valve are all located inside the steam dome. In the cab, the throttle is connected to the regulator valve. To regulate the amount of steam supplied to the cylinders, the engineer operates the throttle. The whistle is a 1925 Baldwin four-chime whistle that is powered by steam pressure. When the pressure rises too high, the safety valve opens to discharge steam.

- Valves, Cylinders, and Pistons: In the cylinders, the steam is transformed into mechanical energy. The piston is driven by steam that is forced via cylinder valves and into a chamber. Lindy uses double-action cylinders, just like the majority of locomotives. By supplying steam on either side of the piston alternately, the piston rod is pushed and pulled, producing power on both strokes, resulting in twice the power.

- Rods: A crosshead operating on a guide aligns the piston in the cylinder. The connecting rod's small end is carried by the crosshead. Using the crank pin, the big end, the opposite end, transfers power to the wheels. To distribute the power produced by the double-action cylinders, Lindy, like the majority of locomotives, has multiple sets of driving wheels. To distribute the power throughout a full wheel revolution, the locomotive's cranks on either side are 90 degrees offset.

- Smokebox: Through the blast pipe beneath the stack, spent steam is expelled from the cylinders. The firebox gases are drawn via the boiler tubes by this method, which lowers the pressure in the smokebox. greater gas is sucked through the tubes as the locomotive exerts greater effort, producing more steam.

- The Stack: After combining with the gases from the boiler tubes, the spent steam from the blast pipe leaves through the stack. More gasses and steam emerge from the stack as the locomotive exerts more effort.

- Cab: From the cab, the train crew controls the engine. By managing the fire in the firebox and the water supply to the boiler, the firefighter's responsibility is to create steam. The engineer controls the throttle to use the steam while keeping an eye on the water, fuel, and steam pressure.

- Sand Dome: For traction between the wheels and rail, the engineer can use the sand in the dome to spray in front of or behind the driving wheels.

Application of Steam Engine

Steam engines were used in all sorts of applications, including

- Factories,

- Mines,

- Locomotives,

- Steamboats.

Story of the Steam Engine

New sources of power were needed because the industry grew rapidly in the mid-18th century. The steam engine was created as a way to turn heat into power and became popular because of this.

French physicist Denis Papin is frequently credited with laying the experimental groundwork for using steam power. Papin created the first pressure cooker in 1679. It was a sealed pot with a tight-fitting cover that held steam inside until it reached a high pressure.

After reading about Papin's research, Thomas Savery created a steam-powered suction device to extract water from coal mines. Savery's device from 1698 had a boiler, a closed water-filled reservoir, and valves as its main parts. Water was forced out of the reservoir through a one-way outlet valve until the pressure of the added steam emptied it.

Water was sprayed on the outside of the vessel to cool the steam. This created a vacuum that could be used to bring up more water through a valve at the bottom. Unfortunately, there was a limit to how high water could be raised because of the formed imperfect vacuum.

Thomas Newcomen invented the atmospheric steam engine. The creation outperformed Thomas Savery's earlier blueprint. Unlike Thomas Savery's 1698 invention, Newcomen's engine did not have its pressure intensity restricted by the steam pressure.

Thomas Newcomen and John Calley constructed their first engine in 1712 to pump water out of a mine shaft filled with water. The Watt engine's ancestor was the Newcomen engine.

James Watt gained notoriety for advancing the steam engine. Watt was tasked with fixing a Newcomen engine, considered the best steam engine of its day but inefficient, while he was employed by the University of Glasgow in 1765. That prompted the creator to begin refining Newcomen's concept in other ways.

Watt's invention in 1769 for a separate condenser attached to a cylinder via a valve was the most significant advancement. Watt's design had a condenser that stayed cool while the cylinder was hot, unlike Newcomen's engine. Watt's engine eventually led to the Industrial Revolution, becoming the standard design for all contemporary steam engines.

Reciprocating engine: A heat engine, sometimes called a piston engine, transforms pressure into rotational motion using one or more reciprocating pistons. There are three main types of engines. The steam engine was used during the Industrial Revolution. The internal combustion engine is commonly found in cars. The Stirling engine is used for specific purposes.

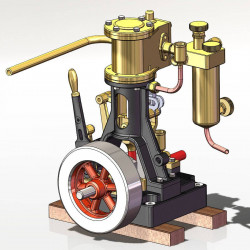

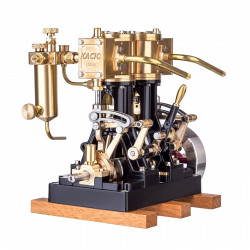

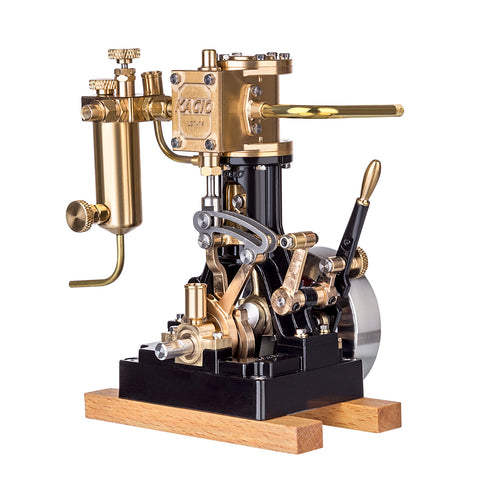

KACIO LS1-14 Single Cylinder Reciprocating Steam Engine Model for Model Ship Model Boat Above 60cm

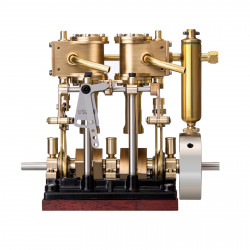

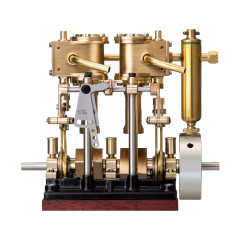

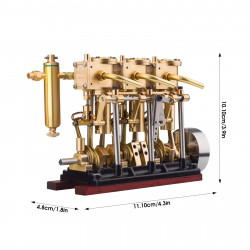

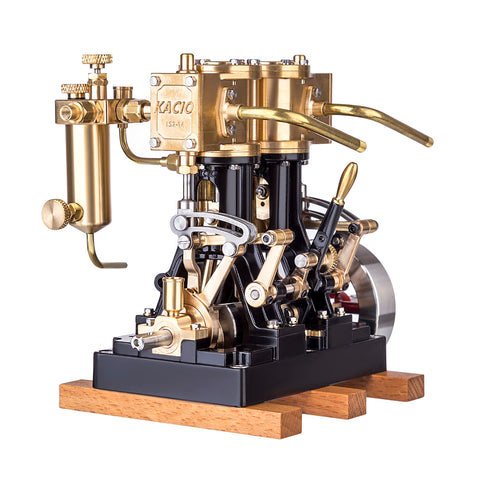

KACIO LS2-14 2 Cylinders Reciprocating Retro Steam Engine Model for Model Ship Model Boat Above 80cm

Features:

.The body's surface is treated with electrophoresis, which will not fade long.

.Integrated CNC steel crankshaft features good stability and high concentricity.

.The joint surface is sealed with a fluorine rubber ring, which is high-temperature resistant and corrosion-resistant.

.Multi-functional oil cup. Excellent lubrication system.

. A lubrication port is provided for each friction surface.

.The spindle sleeve is made of high-hardness of beryllium copper

.Large cylinder diameter and large stroke provide mighty power for the ship

.High power requires an efficient boiler. There is no boiler included. You can purchase it for yourself and get our advice regarding a boiler that matches.

.People adore it because of its elegant and tiny form, which resembles a gem. It is a valuable addition to any collection and a superb mechanical handcraft. A surprise present fit for fans of Steam models

FAQs.

Who invented the steam engine and when?

In 1712, Thomas Newcomen created the first commercially viable engine that could supply a machine with constant power. In 1764, James Watt made a crucial advancement by transporting spent steam to a different vessel for condensation, significantly increasing the amount of labor produced per unit of fuel used.

What was the steam engine and why was it important?

There are many different applications for steam engines. The earliest steam engines were rudimentary pumps to extract water from mineshafts. Following these advancements, trains, ships, and entire factories were powered by more potent and efficient steam engines.

Why did we stop using steam engines?

Steam power for commercial purposes gradually ended due to the demise of the ironstone quarries, steel, coal mining, and shipbuilding sectors, as well as the abundance of outdated British Rail diesel shunters available as substitutes.

Are steam engines still used today?

Steam locomotives are still in use in Eritrea for commercial and irregular revenue purposes. In North Korea, steam engines have begun to be used again due to oil shortages. German-built steam locomotives from World War II are still in service in the coal mines in the Tuzla region of Bosnia and Herzegovina.

What are the negatives of the steam engine?

Compared to other heat engines, steam engines are less efficient. Coal and other fossil fuels are used in steam engines to produce heat or steam. Due to the rise in greenhouse gases in the atmosphere, which causes climate change and global warming, these fossil fuels pose a threat to the ecosystem.