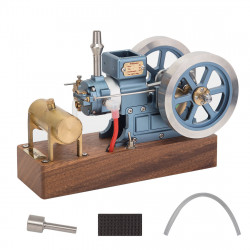

Motor Stirling

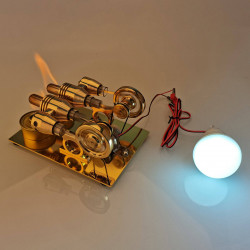

One kind of heat engine is the Stirling engine. It functions by using a gas's expansion and contraction. This gas moves cyclically from a hot region where it grows to a cool focus where it contracts.

Robert Stirling created the Stirling engine in 1816. He is credited for helping to develop hot air engines. A less hazardous engine than the steam engine was the aim.

The Stirling engine was initially intended to be an industrial primary engine that would rival the steam engine. In reality, it was limited to low-power motors and residential uses for over a century.

Investigations into development are ongoing. It is quite versatile because all you need is an external heat source. This characteristic makes it possible to operate it using a variety of energy sources, including hydrocarbons and solar energy.

How does a Stirling engine work?

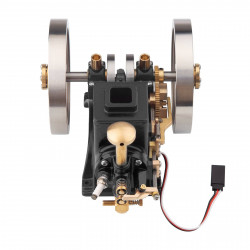

Thermodynamically "closed" regenerative cycle of the Stirling engine. It operates by compressing and expanding the working fluid cyclically at various temperatures.

A gas's compression and expansion cycle is known as the Stirling cycle. It functions by causing a gas to expand and compress. A net conversion of thermal energy into mechanical work is achieved by using two different temperature levels.

The Stirling engine is conventionally categorized as an external combustion engine, just like the steam engine. The engine wall facilitates all heat transfers involving the working gas. The heat source is external, which sets it apart from internal combustion engines.

The Stirling engine, in contrast to a steam engine, shuts off a certain volume of fluid in a permanently gaseous condition, like air. In contrast, the working fluid in a steam engine changes phases from a liquid to a gas.

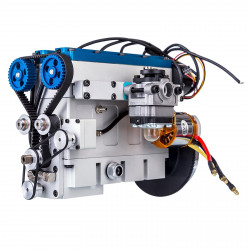

The displacer cylinder is where the pressure variation takes place. The cold zone is where the displacer is located. The crankshaft and flywheel are rotated by the heat generated here. Thermal energy is thus transformed into mechanical energy.

The effectiveness of the Carnot cycle severely limits the process's efficiency. The Carnot cycle states that the temperature differential between the hot and cold tanks determines efficiency.

Stirling engine characteristics

The Stirling engine is characterized by:

- Its high efficiency compared to steam machines

- Quiet operation

- Ease with which almost any heat source can be used.

As the price of traditional fuels has increased, compatibility with renewable and alternative energy sources has become more crucial.

Stirling cycle

The ideal Stirling cycle consists of processes:

At point 1, the gas is highly pressurized and at a high temperature.

- 1-2 isothermal expansion of the working fluid with the heat supply from the heater.

- 2-3 is equivalent to the hot gas's isochoric heat being removed and sent to the regenerator. Process at a steady volume.

- 3-4 isothermal compression of the working fluid with heat removal to the refrigerator.

- 4-1 heating the working fluid isochorically using the regenerator's heat supply. Process at a steady volume. The temperature of the gas is lower at this stage.

Stirling engine applications

Stirling engines are used in many different domains, including propulsion and mechanical output.

Among other applications, these engines have been utilized in the marine propulsion sector and the automotive industry. Good performance can be achieved in comparison to heat engines.

Generating electricity with solar and nuclear energy. Applications for solar and nuclear energy are present in this instance. Using these resources as a source of heat to power a steam turbine is the issue in both situations.

Stirling engines are capable of acting as heat pumps. We are grateful for these devices' heat exchanger and reversible nature.