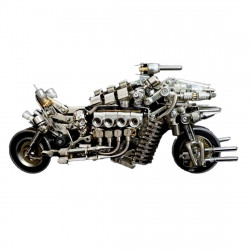

Established in 2000, Cison Engine Ltd is a Chinese company that has been producing and distributing RC and internal combustion engines since 2019. We are renowned for creating highly desirable engines.

Consumers frequently return to purchase another engine for themselves or a close friend. Since 2021, we have collaborated with stirlingkit.com and have been shipping daily worldwide.

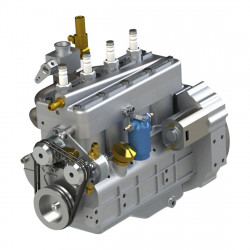

The most recent CAD software was used to develop, prototype, and extensively test our new engine. One of our newest products, the Cison v2 engine, is well-liked by clients worldwide. The second RC engine we manufacture is the Cison inline-four engine. Naturally, pre-orders for Cison inline-four engines are currently available at v8engineforsale.com.

Why we need your help

Creating our engines involves months of designing, testing parts, and making prototypes until they meet our standards. Like earlier engine development, multiple design iterations are required before reaching a final, functional prototype.

We could make a few engines quickly by starting production on a small batch tomorrow, but it will be expensive. What makes a small batch run pricey? We will use our own lathes and milling equipment at our workshop to machine each part. However, the CNC machines must first be configured and programmed to produce a batch of parts, which typically takes several hours for each component.

Since CNC machines are expensive, it is customary in the industry to charge for setup time for each batch of parts. For instance. If ten parts are produced at a setup cost of $8,000 each, each part would cost $800 plus the cost of raw materials and machine time. However, the price per item would only be $8 if 1000 were produced, including the raw material and machine time.

The cost of tools is high. We need to make tooling for our CNC machines. The tooling should securely hold the raw material. It should also allow for quick and efficient machining.

Carefully planning the tooling and producing many pieces simultaneously maximizes production, allowing the machine to make more parts more quickly. Costs are significantly lowered as a result.

By purchasing in bulk, we can reduce the price of the materials when we make a good-sized batch. While not much will be saved, every little bit helps.

We can decrease manufacturing costs by over 60% by increasing the batch size and optimizing tools for more effective machining. Simply put, we need your assistance in creating tools for each part. We also need help in programming the CNC machines to efficiently produce the parts.

We can complete the project (pre-order) with your assistance!

Cison Engine Guarantee

Every engine we sell comes with our UNwavering guarantee that it will perform as promised. We promise to help you as much as we can if your engine doesn't work as promised. To ensure your engine arrives safely, each Cison engine will be individually wrapped in strong cardboard tubes and protective packaging. Every Cison engine will undergo comprehensive testing, assembly, and machining at our workshop before shipping.

Chinese engineers and designers

We manufacture every component for this engine in our state-of-the-art, CNC-equipped workshop in China. This provides complete control over the precision parts that go into our engines and enables us to maintain extremely high standards.

In 2000, Cison Engine Ltd was established in China. Since then, we have created innovative and captivating internal combustion model engines. We are very satisfied with employing top-notch engineering to create beautiful engines. Our engines demonstrate our twelve years of experience with ICE engines.