Why Does Porsche Use Boxer Engine

Among the most recognizable sports car companies, Porsche is notable for its distinctive engine selection, svelte styling, and powerful automobiles. For decades, Porsche has distinguished itself from other automakers by using boxer engines.

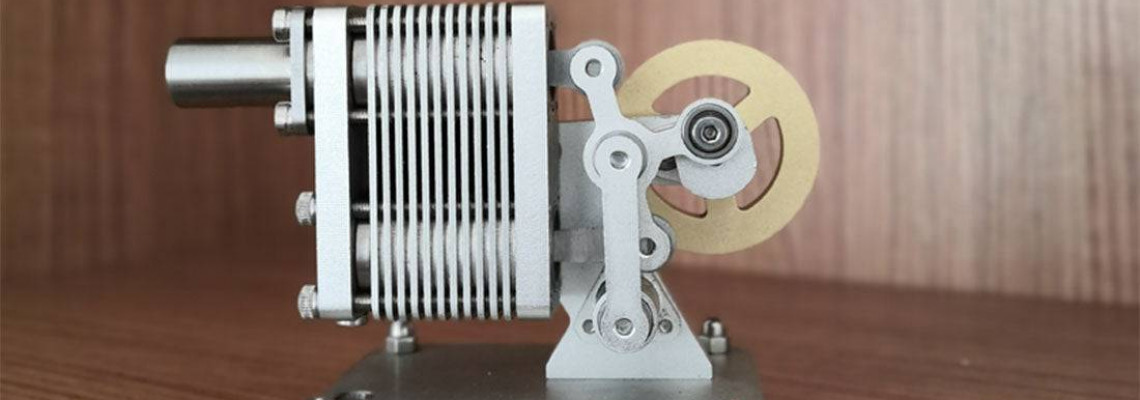

What is a boxer engine?

The cylinders of horizontally opposed engines, sometimes called "H-type engines" or flat engines, are positioned horizontally. The boxer engine is the most often used flat engine type, where the pistons of each opposing pair of cylinders simultaneously travel inward and outward. One kind of flat engine is the boxer engine. The engine pistons in this arrangement travel horizontally, to the left and right, and are equally spaced on either side of the crankshaft. This design lowers the vehicle's center of gravity, improves its smooth functioning, and shortens the engine's total height and length. The torques produced by the pistons on either side of the engine counterbalance one another when installed at the vehicle's center line, significantly lowering vibration when driving. The noise levels have decreased, and the engine speed has increased dramatically.

Although horizontally opposed engines have been used in the past by several brands, including Ferrari, Lancia, Alfa Romeo, and Chevrolet, Porsche and Subaru are currently the main users of this technology. Porsche is proud of its proficiency with horizontally opposed engine technology, demonstrated by vehicles like the 911 and 718 (Cayman and Boxster). Other brands, however, have chosen to stop using this technology after weighing the benefits and drawbacks.

What's so good about boxer engines?

A boxer engine's low center of gravity is one of its main benefits, and it fits in nicely with sports car specifications. The engine's structure reduces overall height and length by parallel aligning the ground, cylinder block, and pistons. This small engine arrangement dramatically minimizes the vehicle's center of gravity, which also takes up less room in the cabin. Many customized cars improve vehicle handling by lowering the center of gravity by moving the batteries and swapping out the shock absorbers. Additionally, the small engine arrangement enhances stability at high speeds by reducing shaking while turning.

A low center of gravity improves handling stability, braking, and dynamics. It also permits more significant cornering limits regarding handling stability. The "flat" cylinder design further enhances driving stability, also lowering the car's center of gravity and producing a low, flat front end.

The second noteworthy benefit is the superior performance, smooth acceleration, and riding comfort of horizontally opposed engines. The balanced piston movement makes higher engine speeds possible, which usually has a 180-degree offset and lowers the crankshaft's balancing weight needs. These engines can operate smoothly even at a low speed of 650 rpm. Additionally, horizontally opposed engines use less gasoline than other engine designs. Because the pistons in horizontally opposed engines travel horizontally rather than up and down like those in inline engines, there is no need to defy gravity. The horizontally opposed engine's self-balancing feature and its structural advantage combine to produce smoother engine operation. Higher speeds and faster acceleration are made possible by replacing balancing components like balance shafts with lightweight crankshafts and flywheels.

Porsche's sports vehicle series, which includes the 718 and 911 models, only use the boxer engine. These engines are ideal for these sports cars since they have a low center of gravity and are easy to drive.

The capacity of boxer engines to reduce noise and vibration is another unique quality. The cylinders' symmetrical arrangement makes it possible to balance out vibrations caused by the piston. The left and right pistons' opposite movement orientations successfully offset one another. The hand won't bounce; it's like bringing the two ends of a long rubber band together and letting go a little in the center. In contrast, the rubber band will bounce off the hand if one end is loosened and pulled taut. The horizontally opposed engine's symmetrical design reduces vibration-related problems.

It is so suitable, why don't other car companies use it?

Horizontally opposed engines have inherent disadvantages and difficulties, which explains why other automakers do not use them extensively.

The engine's poor torque performance and lubrication problems are two main worries. The intricate structure of the horizontally opposed engine makes it difficult to achieve adequate oil lubrication. Compared to V-shaped or L-shaped configurations, the horizontal cylinder placement produces shorter crankshaft moment arms and cylinder bores. The engine's low-torque performance is, hence, inherently poorer. Because of gravity, oil builds up at the piston's bottom, leaving one side of the cylinder with insufficient lubrication. The efficacy of the lubrication is severely compromised due to less lubricating fluid at the top and too much oil at the bottom.

Furthermore, maintaining horizontally opposed engines is more expensive due to the precision needed for manufacturing. Layout flexibility is further hampered by these engines' broader body design. The cylinder liner's upper and lower inner surfaces wear unevenly due to the piston's horizontal reciprocating motion, which is influenced by its gravity. A large amount of the engine's total friction loss is caused by friction between the piston ring assembly and cylinder liner. As shown with the Subaru EJ257 engine sold in North America, this discrepancy in wear patterns can result in issues including cylinder scuffing and cylinder explosions.

Wear and uneven lubrication can be fixed, but solutions such as specialty lubricating oils are more expensive. To guarantee enough oil pressure, Porsche 911 models, for example, need three oil pumps; some high-end vehicles even have five pumps, raising the engine oil price. Improvements in material technology have also helped to lessen the issue of uneven wear.

Moreover, the production of horizontally opposed engines is more costly and complex. Compared to an inline 4-cylinder engine, a horizontally opposed 4-cylinder engine with double overhead camshafts requires more camshafts and intake and exhaust systems. Both sides have different mold components due to the differing layout and piston distribution, which raises manufacturing costs and necessitates the manufacture of separate molds. To guarantee engine efficiency and longevity, precise calculations and designs are needed for elements like intake and exhaust angles, combustion chamber airflow shape, and valve structure, increasing design complexity and production costs. Horizontally opposed engines also require a complex assembling procedure, especially when symmetrically splicing the two center cylinders together. The engine's service life may be shortened by piston wear in the cylinder caused by a minor assembly fault.

Horizontally opposed engines are more difficult to disassemble and install spark plugs because of their broader body and longitudinal engine configuration. Additionally, because many parts for horizontally opposed engines must be imported, maintenance costs are typically more significant due to the lower adoption rate.

The high strength requirements for the engine's motion pair present another difficulty. Significant tensile stress is placed on the crankshaft in the 180-degree alignment quadrant when opposing pistons simultaneously move to either the top dead center or the bottom dead center. Thus, careful crankshaft and connecting rod strength design is essential for the kinematic pair of horizontally opposed engines.

In the end, other automakers decide against extensively using Boxer engines because they do not believe there is a strong enough need to overcome the difficulties and disadvantages of this specific engine type.

Development of the Porsche Boxer Engine:

Porsche started with a 2.0L air-cooled 6-cylinder engine before developing the horizontally opposed engine. The Porsche 911 was intended to be a high-performance sports vehicle from the start, and its engine was equipped with expensive and sophisticated technology. The 911's engine compartment was constrained by its air-cooled architecture, rear longitudinal engine location, and rear-wheel or four-wheel drive setup. At first, Porsche only gave the engine 2.7L of room.

An increase in engine volume was required as the 1970s drew near due to rising horsepower demands, the advent of catalytic converters, and the use of unleaded fuel. Porsche made advances by fortifying the cylinder block, decreasing the thickness of the cylinder wall, and expanding the cylinder diameter, all based on their acquired technology and racing expertise. Electronic fuel injection and high-strength metal components significantly increased the engine's maximum speed and output. The 911 engine's improved layout, which had a volume of over 2.7L, prevented the need to enlarge the rear end while keeping compatibility with standard automobiles, even if the overall engine size increased slightly. The small size of the rear engine compartment and its short shape and slip-back made it challenging to fit a larger engine, so a flat-four design was eventually chosen.

One of Porsche's most recognizable technologies is the horizontally opposed engine. Porsche substantially improved power by coupling the horizontally opposed engine with direct fuel injection. This engine layout was successfully used in the Boxster and Cayman, two smaller sports cars, and reached its maximum potential in the 911 series. Porsche's cultural history includes using horizontally opposed engines, which have been carried down through the decades. It is essential to the brand's identity due to its distinct tuning style and performance attributes.

Porsche Boxster/Cayman Engine Structure:

The Porsche Boxster, Cayman, and 911 basic and S-series vehicles have all-aluminum crankcases created with a unique cold-casting technique. Thanks to this method, Porsche is able to increase the stiffness of the housing while reducing weight. As a result, a single closed cylinder waterway connects a closed crankcase with integral crankshaft bearings.

Porsche Boxster/Cayman Engine Piston Linkage:

Forged aluminum pistons are utilized in the Porsche Boxster and Cayman engines to reach high-performance objectives securely. Improvements to the piston rings reduce frictional losses. Newly developed connecting rods with improved fatigue strength and hardness transfer power to the crankcase. The low compression height and the optimized piston and connecting rod design allow for the development of related components with the optimal power-to-weight ratio. Engine running is made smoother by the reduced inertial force, which also lessens the strain on the crankshaft drive mechanism.

Porsche Boxster/Cayman Engine Intake Control Mechanism:

Based on the results of numerous simulations, Porsche has refined the design of the intake port and valve seat ring in the Boxster and Cayman engines. These steps facilitate the production process and provide adequate intake airflow. High typical output power and torque numbers are the result. The intake and exhaust camshafts have also been adjusted to improve gas exchange and increase maximum torque and power output. Furthermore, the VarioCam camshaft control system is used in Porsche boxer engines. It uses a "vane controller" and a "hydraulically operated plunger" to modify the intake valve timing. This system uses map control to control intake valve lift within a range of maximum and minimum levels.

The Longevity of Porsche's Boxer Engine: The Real Reason

Horizontally Opposed Engine Structure:

A low center of gravity is the effect of the engine's weight being concentrated beneath it by its horizontally opposed construction. This intrinsic benefit greatly improves the vehicle's handling. This feature is just enticing to Porsche, a company committed to sports performance.

Turbo Response Speed:

Although the horizontally opposed engine contributes to this advantage, Porsche's VTG (Variable Turbine Geometry) system is the real star. This system affects the turbine's responsiveness by modifying the angle at which the exhaust stream interacts with the turbine blades. To put it simply, the engine's electronic control unit (ECU) can adjust boost levels and turbo reaction speed to suit varying power requirements.

Weight Distribution of Horizontally Opposed Structures:

Porsche vehicles with horizontally oriented engines are usually mid- or rear-mounted. The engine's design evenly distributes weight on the rear axle, keeping the left and right sides of the engine at a 50:50 weight distribution. This weight distribution improves traction, particularly when paired with the boxer engine's rear placement.

Smoothness of the Horizontally Opposed Engine:

Porsche values sleek body lines and has contributed significantly to the 911 series' long-term success. Nevertheless, this design strategy needs more room in the engine compartment. Porsche's compact size advantage allows it to securely fit the horizontally opposed engine despite the difficulties caused by stringent space restrictions.

A small and light engine may produce significant power thanks to the horizontally opposed engine configuration. Because of its small size, the engine may be positioned lower, which lowers the center of gravity. As a result, Porsche sports vehicles handle things much better, especially when it comes to turning. Mounting the boxer engine in the back dramatically improves traction because the weight distribution favors the drive axle. Additionally, the horizontal configuration increases fuel efficiency when engine power increases. The Porsche 911 engine's low center of gravity and lightweight design provide outstanding performance while appropriate for daily driving.

Porsche has found that its quest for performance and control is well matched with the horizontally opposed engine. Because of this, the brand has stuck with this engine design. Ultimately, it comes down to appropriateness and compatibility with Porsche's performance-focused mindset rather than whether it is good or terrible.