What is the hit-and-miss engine?

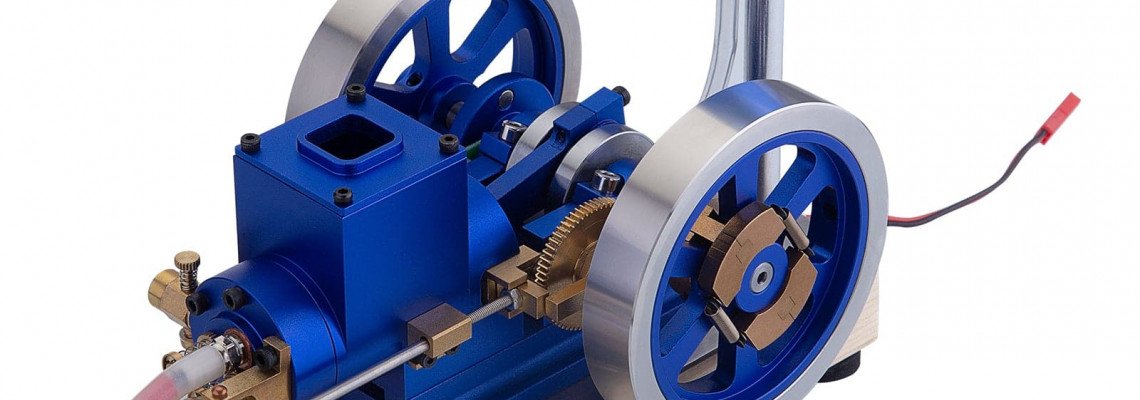

The hit and miss engine was a standard four-stroke internal combustion engine used from the late 1800s to the 1940s. It runs on a fixed speed that a governor manages.

The engine works by "hitting" or firing only when it runs at or below a set speed. It "misses" or does not fire when it runs above that speed. This is how it got its name. Its speed control system sets it apart from engines that are throttle-governed.

Flywheel engines, such as hit and miss engines, are attached to the crankshaft by a big flywheel or group of flywheels. During the combustion stroke, the flywheels store energy. This energy is released to the mechanical load during the other three piston strokes.

Engineers built these engines when technology was not as advanced. They made most parts large and used cast iron.

A miniature hit and miss engine's fuel system comprises a fuel mixer, check valve, fuel line, and fuel tank. While gasoline is the engine's primary fuel, diesel or kerosene are cheaper options.

A mixer connects a weighted or spring-loaded piston to a needle valve to form the fuel mixture. An ignitor or spark plug creates sparks to ignite the fuel mixture. It is powered by a magneto or a battery and coil system.

In hit and miss motor engines, someone mainly lubricates by hand. The connecting rod and central crankshaft bearings are in grease cups. Oil is constantly injected into the piston through a drip oiler. While the engine is running, the operator must occasionally lubricate the engine's other moving parts.

"Open crank" engines, where every component is visible, are commonly found in hit and miss engines. Because of the engine's ability to spew oil and grease, this design creates a dirty environment. You also need to clean it frequently to avoid excessive wear and malfunctions.

Hopper cooling absorbs heat from the engine using water in an open reservoir, providing cooling for most hit and miss engines. Some tiny engines include an integrated fan to help with air cooling. On the other hand, water-cooled engines are more prevalent and frequently need their cooling water tank.

These engines were employed in various settings, including farm machinery, saws, cement mixers, pumps, and generators. They were especially well-liked on farms since they gave farmers a labor-saving tool. Usually, hit n miss engines were connected to their powered equipment via a broad, flat belt.

Flywheel engines were heavy and slow. Because of this, they became less common in the 1930s.

More advanced engines took their place. Popularity increased for enclosed crankcase engines with self-lubrication, dependable spark plug ignition, and reduced weight. Some situations still employ modern flywheel engines because they prefer low speed, particularly in oil field applications.

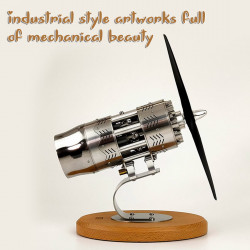

Many hit and miss engines were scrapped during World War II, but many enthusiasts have kept and rebuilt them. These engines are on display at steam fairs, antique vehicle rallies, and antique engine exhibits. However, this mini hit and miss engine model will soon be available on V8engineforsale, so check back soon!