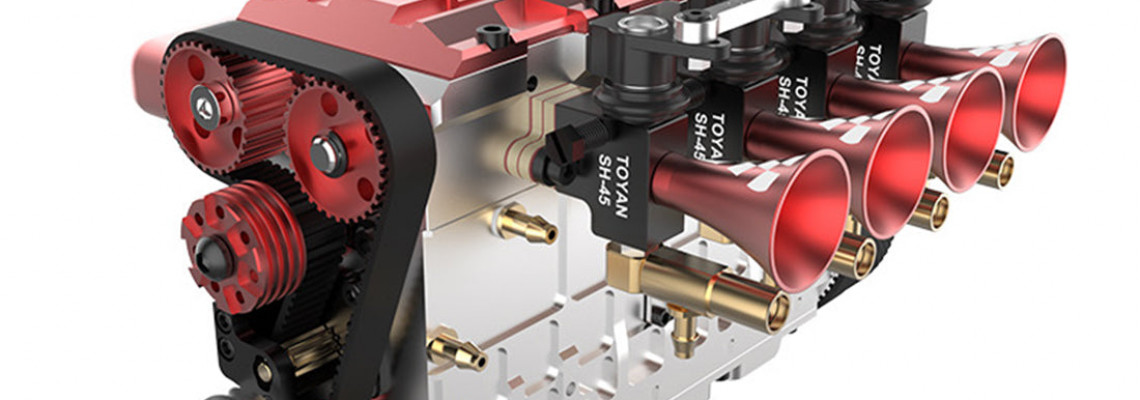

Top 12 Common Mistakes that Toyan V8 Engine Owners Make

Undoubtedly, having a Toyan V8 engine model is a wonderful experience, but new owners might need to learn how to start it up. Understanding the engine's operation and performance is crucial for a smooth start-up. Engine damage could result from failing to accomplish this. Here are 12 typical errors that many new owners of Toyota engines may make to help prevent this.

1. Failure to add engine grease regularly as required:

Add the grease after opening the hood. The team uses the mounted camshaft. Kindly add the solid grease to guarantee steady functioning and prevent the camshaft from becoming dryly frictional.

2. Oxygen deficiency in the system:

Check the intake system for air leaks. Clean the valves and change the air filter. Also, inspect the spark plugs and valve parts for damage.

3. Invalid high-pressure oil pump:

Examine the oil pump's power source, the control circuit for the oil pump, the oil pump gasket itself, and any of its accessories. Replace any broken parts.

4. Invalid fuel injector:

Check the fuel injector for dirt, measure the fuel flow, inspect the circuit, and replace any damaged fuel injectors.

5. Ineffective exhaust system:

Check the exhaust pipe, manifold, and valve for damage or leaks, then replace any broken parts.

6. Ineffective cooling system:

Keep the cooling water level steady. Fix any broken parts. Check the water pump, fan, and radiator. Look for leaks in the cooling system.

7. Engine vibration:

Check the engine mounting bolts. Look at the intermediate shaft and connecting rod to see if they are loose. Check the crankshaft and camshaft for wear. If the intermediate shaft or connecting rod is worn out, replace them.

8. Ineffective ignition system:

Check the spark plug and wire for damage. Inspect the high-voltage and intermediate wires. Monitor the air conditioner spark plug pressure. Replace any broken spark plugs.

9. The air intake system is blocked:

Check the air intake pipe for leaks. Look for carbon buildup in the air inlet.

Search for obstructions in the air intake pipe. Clean the air intake pipe. Fix any broken sections.

10. Wrong Camshaft Angle:

The camshaft angle must be adjusted correctly to guarantee that a V8 engine will start and run correctly. The engine's performance will suffer if the camshaft angle is too big or tiny.

A large camshaft angle makes the intake valve open too slowly. This leads to wrong combustion timing and less engine power.

A small camshaft angle makes the intake valve open too quickly. This changes the air and fuel mixture. In the end, it hurts the engine's performance. The camshaft angle must be set correctly to ensure the V8 engine runs well and starts smoothly.

11. Failure to detect the starting system:

Check the starting system circuit. It usually includes the battery, starting motor, and the cables that connect them. It also has the ignition switch, starter relay, and the vehicle's anti-theft system.

12. Ignition timing is incorrect:

Check if the timing belt is slipping to prevent the engine from starting owing to a lack of electric spark.

Frequently Asked Questions People Might Ask.

Why is it Hard to Start a Gasoline V8 engine Model?

The gasoline Toyan V8 engine model is complex to start for a variety of reasons, chief among them being the following:

One is the model's inherent complexity. To accurately replicate the operational characteristics of the actual engine, the gasoline model v8 engine has a complex structure. It requires many parameter adjustments, including cylinder volume, valve delay, fuel injector control, etc. The model will only work successfully if the parameters are set appropriately.

The second is the unpredictability of the engine's working environment. A gas V8 engine works differently than in a lab.

A lab has specific needs and is affected by outside factors. These factors include temperature, air pressure, and air pollution. Changes in these conditions can greatly affect how well gasoline engines start.

The third is the unpredictability of parts for V8 engines. A gasoline engine consists of several tiny pieces. Since each component's precision and quality impact the engine's performance, an engine's starting performance will also be impacted by an unreliable component.

A flaw in the engine control system is the fourth. The performance of the gasoline engine simulation model is affected by problems in the engine control system. These issues stop it from simulating how the engine runs accurately.

In conclusion, the model's complexity, the engine's operating environment, and the unreliability of its parts make starting hard. Flaws in the engine control system also contribute to this problem. To enhance the start-up performance of the engine simulation model, you should carefully consider the following parameters while using a gasoline engine simulation model.

So, How do Start the Toyon V8 Gasoline Engine Model?

Before starting the tiny Toyan V8 model, check the condition of all engine parts. This includes engine oil, fuel, valves, pistons, and the crankshaft. Also, inspect the connecting rods, brakes, timing belt, and fuel injectors. Don't forget to check the exhaust pipes, spark plugs, engine coolant, and air filter.

Lastly, look at the air conditioning system and its power supply. Make sure to check the air conditioner filter as well. Do this twice for safety. To maintain the proper operation of your Toyan engine, each failed component must be either repaired or replaced.

Second, remember to check the engine's electrical system. This includes the starter, battery, and engine setup. Also, look at the electrical parts, engine control system, sensors, and engine control unit. To maintain the V8 engine operating correctly, inspection and repairs are necessary if the electrical system malfunctions.

Third, this V8 engine has a high speed that might be hazardous, and it is advised to run it on 95 # pure gasoline. Please follow the directions precisely as they are written!

Only add gasoline (92, 95, and 98) and nothing else. In certain nations, the names of gasoline models may differ. An octane level of 91 or lower cannot be added to gasoline; 95 is the preferred value.)

Keep the gasoline separate from the ignition source and ensure it stays clean! Fuel with many contaminants may clog the fuel injection carburetor oil passage, lowering engine performance. (Please use 2T engine oil and change the gasoline fuel ratio to 1:25 to 1:30).

The FS-V800G has a four-stroke gasoline engine, so it needs eight specific spark plugs. A unique CDI is necessary for the spark plugs to control ignition. The spark plug and gasoline will catch fire when Hall detects the piston at the top. Then, the generator will start working.

Remind!

The spark plugs will only last for a while if the engine operates at high speeds. Please note that engine fuel can pose hazards to human health.

Steer clear of tongue or eye contact, store in appropriately labeled containers, and keep out of children's reach. It catches fire quickly. Stay away from sources of ignition, high temperatures, and open flames.

Additionally, someone needs to inspect the fuel system of the little Toyan V8 model before starting. This entails checking the diagram fuel pressure regulator, fuel lines, fuel filter, fuel injectors, fuel pump, and more. Inspection and repairs are necessary to ensure the engine operates correctly if the fuel system fails.

Finally, you must examine the engine's emissions system before turning on the small V8 model. This includes inspecting oxygen sensors, high flow catalytic converters, exhaust pressure sensors, exhaust pipes, mufflers, exhaust pipe connectors, and more. To ensure the engine operates correctly, someone must examine the exhaust system and fix it if it fails.

What would happen if a gasoline v8 miniature model ran on methanol fuel?

Using methanol fuel in gasoline V8 models can reduce power, increase fuel use, and shorten the engine's lifespan. Methanol fuel can dirty the engine's combustion chambers. This leads to blocked spark plugs and incomplete combustion. As a result, the engine has less power and lower fuel efficiency.

Using methanol fuel will shorten the service life of the small gasoline V8 engine. It will reduce its emission performance and make it fail local emission regulations.

When using petrol V8 mini models, it is best to use petrol fuel. This helps achieve better results, save energy, and reduce emissions. Similarly, gasoline fuel has a distinct composition, and you should only use it with methanol model engines. Using gasoline fuel can reduce combustion efficiency, engine damage, and even explosions.

Can the methanol engine be changed to a gasoline version?

Indeed, converting a methanol engine to a gasoline engine involves a significant learning curve. Safety and dependability are the two most crucial factors to consider before a conversion.

Gasoline engines are designed to use gasoline. Methanol engines are made to use liquid energy. This creates big differences in how the two engines are built. This means that several adjustments must be made to convert a methanol engine to a gasoline engine.

These changes include adjusting the size of the engine's combustion chamber. They also involve improving the engine's cooling system.

Additionally, we will change the engine's fuel system. We will modify the fuel injector and nozzle as well. Finally, we will adjust the flow rate of the gasoline pump. All these alterations and adaptations show that turning a methanol engine into a gasoline engine is a complex process that takes time and work.

More crucially, the ignition systems of gasoline and methanol V8 engines are different. Whereas gasoline engines employ spark ignition, methanol engines use electric heating.

When a methanol engine runs, an igniter heats the head until it glows red. At this temperature, the methanol warms up and ignites by itself as the piston pushes the mixture to the top. The hot plug will remain red hot for as long as the succeeding combustion produces heat.

On the other hand, gasoline engines cannot ignite on their own, and gasoline has a comparatively high ignition point. Methanol can be used in gasoline engines. However, it is incompatible with the lubricants used in micro-engines, like those found in vehicles.

Converting a methanol engine to a gasoline engine is typically challenging. The methanol engine's cylinder needs a more excellent compression ratio, and the spark plugs must be changed. Furthermore, starting a gasoline engine is more challenging than starting a methanol engine. Consequently, it is advised to refrain from performing the conversion.

Furthermore, there is a noticeable difference in the power output of gasoline and methanol engines. To change a methanol engine to a gasoline engine, the power needs to be adjusted. It must match what a gasoline engine needs.

This change needs help from technical staff. It also requires special engine tuning tools. This ensures the engine works at its best.

For a challenge, consider working with tiny gasoline engine spark plugs that need an igniter in addition to a magneto. This configuration is comparable to a gasoline engine with two strokes.

You should have these spark plugs custom-made because, regrettably, they are not yet for sale. This can be difficult since it requires specialized knowledge and exact adjustments to the primary and secondary oil needles. In addition, two-stroke special oil needs to be used in gasoline engines.

What should you do if you change the methanol engine model to the gasoline version?

- Replacing fuel:

Switching from methanol to gasoline requires replacing the fuel pump, fuel injector, fuel filter, and other equipment.

- Adjust combustion chamber parameters:

To obtain a shorter combustion period, the combustion chamber characteristics of gasoline engines are lower than those of methanol engines;

- Adjust the supercharging system:

To provide a more effective supercharging effect, the gasoline engine's supercharging system is more intricate than the methanol engine's.

- Adjust the ignition system:

For the gasoline version, new spark plugs, ignition coils, ignition controllers, etc. are required;

- Adjust the combustion control system:

The circuit must be modified since the gasoline engine's combustion control system is more intricate than the methanol engine's.

- Adjust the cooling system:

The cooling systems need to be replaced because gasoline and methanol engines require different cooling methods.

- Adjust the intake system:

Compared to the methanol engine, the gasoline engine's intake system characteristics are more stringent. The methanol engine's intake system and the gasoline engine's intake system are not the same. Intake air temperature sensors, injectors, etc.

- Adjust the exhaust system:

The exhaust manifold and catalytic converter may need to be replaced. This is because the exhaust systems of gasoline and methanol engines are different.

- Change the lubrication system:

The oil pump, filter, cooler, and other parts need to be changed. Gasoline and methanol engines use different lubricants.

Converting a methanol engine into a gasoline engine is complicated. Engine debugging tools and qualified specialists are required to guarantee the modification's dependability and safety.