How does a Vacuum Engine Work?

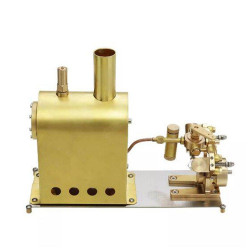

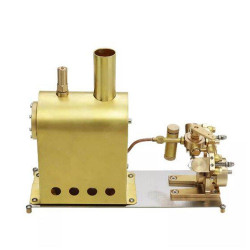

What's a Vacuum Engine?

Air pressure against one side of the piston, which has a partial vacuum on the other side, provides the force for a vacuum engine, also known as a flame-licker engine, flame-engine, flame-eater engine, or flame-dancer. A valve in the cylinder's head opens at the start of an out-stroke, admitting a charge of burning gas and air that is trapped by the valve's closure and expands. As the stroke comes to a finish, the charge contacts and cools a water- or air-cooled section of the cylinder, resulting in a sharp drop in pressure that pulls the piston, which is open toward the crank, back on the return stroke. Before the subsequent out-stroke starts, the valve opens once more to allow the piston to release the burned gasses.

How does a Vacuum Engine Work?

An external pump generates the partial vacuum in a vacuum motor. In the UK, these motors were frequently employed to power railway turntables by harnessing the vacuum produced by the vacuum brake ejector of a steam engine. Power is drawn from a differential in pressure in both systems, which is similar to how a steam engine works.

The vacuum engine depends on a steady heat source from burning fuel, in contrast to the ideal Otto cycle engine. As previously stated, a valve permits heat to enter the piston chamber. The ideal gas equation PV = nRT suggests that the piston chamber's pressure will rise if the heat in or Qin is constant in the controlled volume region. The piston goes through an adiabatic process during the downward stroke after the valve closes. The chamber is cooled by the surrounding air or water when the piston hits the bottom of its stroke, and the consequent Qout causes the piston's pressure to drop. After that, the system compresses the gas in the chamber adiabatically once more. The gas is then released by the valve at the top of the cylinder's stroke, allowing fresh hot gas to enter the chamber at the same time.

The model's incredibly low efficiency in practical applications was one of the main problems this engine faced during development. Only a tiny percentage of the potential fuel is being used to power the engine since the heat source is not localized. Only a tiny portion of the burning fuel is being utilized to power the engine in a vacuum engine since engine efficiency is determined by the relationship between the quantity of work performed and the potential energy in the fuel consumed. The surrounding atmosphere absorbs the remaining fuel energy.

Although the most incredible power that can be transferred to a vacuum motor is lower than with traditional pneumatics, a vacuum system can be employed for power transmission. As demonstrated by Downie, a vacuum power transmission system operates best at a pressure of about 0.4 bar (8 psig). It can be entirely feasible even though it is less effective than pneumatics. On 0.4 bar (8 psig), for instance, a 22 mm (7/8") pipe under vacuum can transmit as much power as a 6 mm (1/4") pipe under 8 bar (100 psig). Boulton and Watt employed vacuum power transmission in their production since the method is so effective. In the factory, the vacuum main was referred to as the "spirit pipe."

Summary

Since the external air pressure drives the operation of the vacuum engine, it is an atmospheric engine (similar to the first gasoline engine). This limits the maximum piston force to the product of air pressure and piston area.

More specifically, it is a vacuum motor, commonly known as a flame eater. He is an open system, in contrast to the Stirling engine, which is a hot air engine.