Build Your V-Twin Motorcycle Engine Model FG-VT9

Many Americans dream of owning a Harley. You may wonder why we designed this V2 engine when you first saw the FG-VT9 engine. This is the tale.

More than a century ago, in December 2020, I discovered a Harley-Davidson Panhead engine on the engine forum. The engine has a cylinder diameter of 16.7 mm and a stroke of 21 mm.

This engine caught my attention when I first saw it, so I made my own miniature V2 engine model based on it. I collect a lot of engines because I like them. While they’re working, I genuinely enjoy them. State. To recover the look and maintain the simulation level as much as possible—including engine noise—I looked up a lot of material on Google and YouTube. However, because the machine is too ancient, I didn’t have an actual engine or even look at it. It can be challenging to acquire, and only a few collectors possess it.

I began developing the strategy in January 2020. This is challenging. I can only use the current data to obtain engine information. Instead of using the Panhead engine’s rocker arm design, I chose one with a similar Ohv structure. Yes, it is simple to process, and I am eager to see how it will shorten my production cycle.

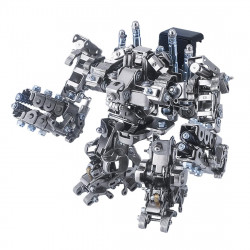

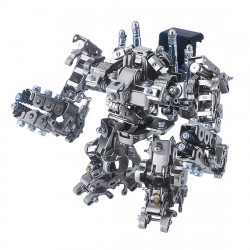

All of the engines will be manufactured using CNC. It is ambient and lovely. Since I enjoy collecting it, I will be upset if I discover that it will eventually turn dark from oxidation. To keep it bright, I’ll use an anodized cylinder surface. The rocker cover will be chrome-plated simultaneously, and its gleaming appearance will lift my spirits.

I spent a lot of time because I could only finish my production in my own time due to my engineering profession. Seven months later, it was finished. I attempted to start, but it was unsuccessful. After that, I began inspecting the camshaft and discovered the angle was incorrect. Because of my prior expertise in designing engines, I assumed the camshaft angles of the two cylinders were equal. My guess is to battle for, and it also needs to add the angle of the ejector rod tilt, according to my simulation of the 3D plan.

I was going to get one of the cylinders to start. I removed the spark plug from the cylinder with the incorrect cam to avoid adding resistance to the cylinder that was ready to start. I tested a Hall igniter that I had welded. He was successful. The sound of the engine is fascinating and lovely.

After I restored the old cam, I asked my excellent friend to construct a new one, and he did it using a cutting machine.

When I started assembling the new cam and verified the ignition time of the two cylinders, I discovered that if the trigger magnet is positioned on the crankshaft’s flywheel, he will require two igniters and two Hall triggers, which is unacceptable, etc., I will add him to the already complete distributor because I began to successfully.

Amazing! It began. This is a fantastic V2 engine that is part of my treasure collection. I am pleased to share the construction design with you, but I may let you miss the engine’s more than 100-year history when you see it. I will then optimize it to near perfection.