A Solenoid Engine or an Electric motor, Which one is better?

What’s Solenoid?

The term “solenoid” was coined by French scientist Andre-Marie Ampere. Eidos means “form, shape” in Greek, and solen means “pipe, the channel." A coil of wire that carries an electric current and functions as a magnet is called a solenoid. It is an essential part of motors of all sizes. It is encircled by a carefully formed iron or steel core.

What’s a Solenoid Engine?

An engine that uses electromagnetism to move the pistons back and forth by passing electricity through coils is known as a solenoid engine. These solenoid types include rotary solenoid, linear solenoid, AC laminated solenoid, and DC C and D frame solenoid, depending on their construction material, design, and purpose.

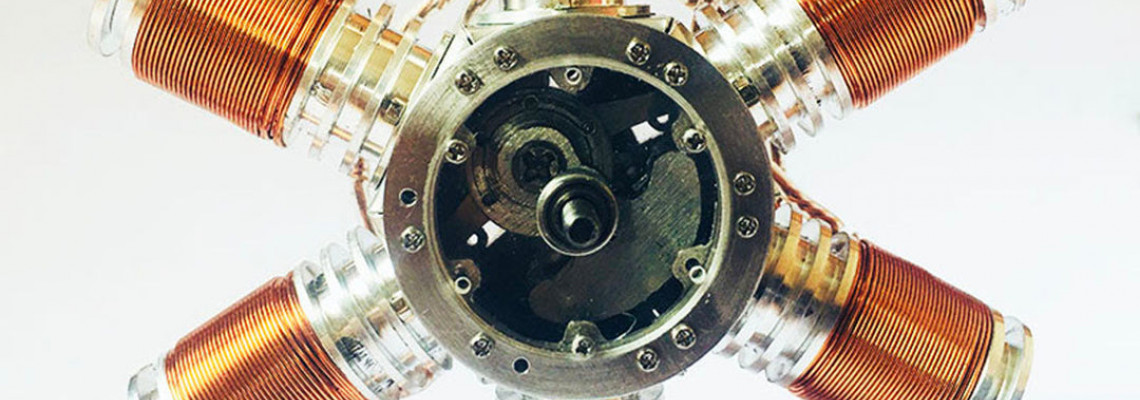

What’s an Electric Motor?

An electrical motor is an apparatus that transforms electrical energy into mechanical energy. It converts electric energy into mechanical energy by passing an electric current through a wire loop enclosed by a magnetic field. Simply put, an electrical motor is a machine that generates rotational energy.

There are two primary categories for electric motors. The AC motor and the DC motor are the two types. Whereas the DC motor requires direct current, the AC motor requires alternating current.

Is a solenoid an electric motor?

An electric motor is a machine that transforms electrical energy into mechanical energy. However, a solenoid is also. One could argue that “motor” is broad enough to encompass any device that generates motion. The fundamental idea behind electromagnetic motors is that every wire carrying current in a magnetic field has some mechanical force. Power output increases with motor size and electromagnetic field strength.

A Solenoid Engine or an Electric motor, Which one is better?

The solenoids have disadvantages but last a lot longer. Their state is binary; the valve would be either open or closed depending on the energization.

Because motor-driven actuators have proportional models, an analog value can determine the valve aperture. Depending on the intensity of the magnetic field delivered to the core, solenoids are made to exert a fixed force. An action that doesn’t deteriorate or age to the point where it needs more force than the field calls for must be combined with this strength.

As the mechanism ages, rotary actuators can be equipped with gearings to increase or decrease the force they apply by expanding their torque profile.

During an outage, solenoids are unable to stay in an energized position. It is possible to make rotary actuators non-spring return, keeping them in place until they get a new command following the outage. Solenoids are the option that will last the longest if you’re searching for a compact, torque-stable, binary linear movement that doesn’t lose power. This is because they’re straightforward and dependable.