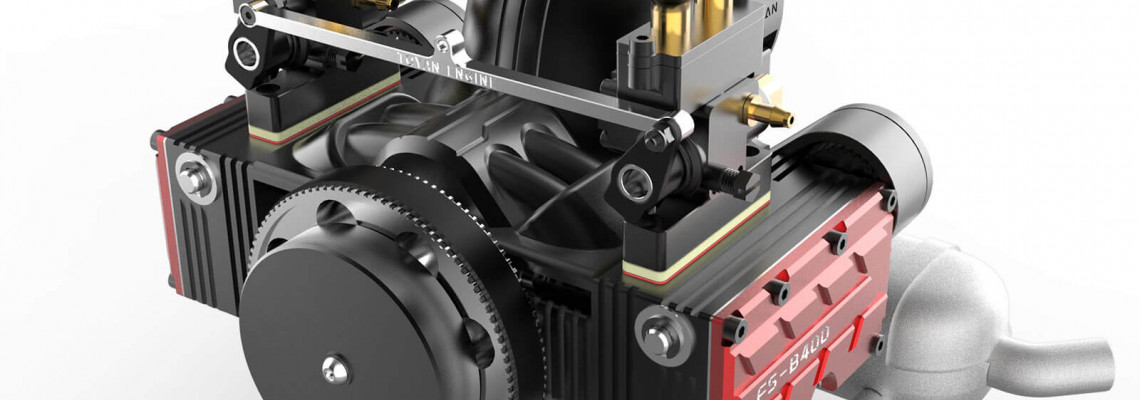

Toyan Rotary Engine is a Monster

I recently received the tiniest rotary engine in the world from the people at V8engineforsale. I will record a video and share it with you to show you how big this little motor is. Everything is small enough to fit in my palm, and the engine functions well.

I've brought the small engine's specification handbook here to see precisely what the 2.46 cubic centimeters per rotor means. Which adds up to 4.92 overall.

It has two plugs, as you can see. We will disassemble the engine to view it from the inside, and we have precisely two rotors. Its two rotors are equipped with carburetors.

We can see precisely here. Look at what it is. This is an artistic engineering creation.

Examine the size of the inserted needle to restrict the passage of air and fuel. Our purpose in being here is to control. To control slow motion as well.

Look at the exhaust system; it's quiet. Nevertheless, we also received a complimentary exhaust system from the folks at Troyan Engines. Additionally, it is possible to hear it using the free exhaust.

Whether it's because of you or myself, I'm going mad. I can't wait to activate it. It functions for between 3,000 and 20,000 revolutions per person.

This machine produces 1.26 horsepower at 19,600 rpm and rotates at 20,000 rpm. As I mentioned, this weighs 446 grams or half a kilogram. I find it unbelievable.

It features multiple ducts. As you can see, this one is an air pump that needs to pressurize fuel; to put it another way, think of it like a gasoline pump. Following that, we have the refrigeration circuit's inlet and outlet. Yes, folks, liquid cooling is what you need to survive.

This engine is authentic. With two rotors, it is the smallest in the world to exist on this planet.

This work of art engine generates 2.82 horsepower per kilogram of power weight. The 4.22 cubic centimeter volumetric performance would give us 256 horsepower per liter ratio.

It's a monster, this. This beast is exactly five centimeters in size, as stated here, neither more nor less. Indeed, folks. An expanded version of the instruction manual describing this little engine and an exploded view is here.

This small engine has extra gaskets. As I said before, we will take it apart to see the inside.

Then, I will put in the extra gasket and put it back together. The entire duct, the water inlet, the outlet, and the cooling system. This is a printed scale representation of the size of a 1.3-liter 13B rotor for your reference.

As you can see, the small motor fits inside the actual rotor. We quickly disarmed it. We took off the component there, and the spare gasket is also here. Observe the worn pattern that it produces.

We can observe how flawlessly she performs the entire dance. That's the admission, then. It's the carburetor here. Go into that vent over there, vacuum. Continue suctioning.

Next, shut the lid and the port. Initiates the stage of compression.

Condense. It explodes right there with the spark plug.

Extend.

The exhaust port is the last item on the list. It exits that hole in the direction of the exhaust pipe.

Since the fixed gear on the housing is lacking in this location—what keeps the rotor dancing flawlessly—I'm helping. There, too, the apex seals are visible in miniature. Take note of the position of the protruding blades.

We can now see the crankshaft as well. Observe the Apex seal.

Take this chance to observe what could turn into the ring's spring. That tiny bit of wire. Look at this little rotor.

We have a real-scale 13 B rotor as a reference in this sheet. I would like you to see how small this little rotor is. The gear and the lengthy combustion chamber are also present.

Now, take off the carburetor. Check out this carb's size. You get the idea; I've never held one so tiny.

Additionally, we disassembled the intake manifold to examine how the air enters. Everything starts here and travels in this direction before entering the cylinder, likewise for the opposing side. This is where everything arrives.

At that point, the cylinder enters. All of this is like an intake manifold. It slightly increases the travel to improve how fast air is drawn in.

These motors have many benefits. They are very light and easy to use. I feel confident again as a rotary motor mechanic.

We fully disassembled the engine here, and we can see the gasket, flywheel, rotor, crankshaft, and casing. ports for the intake, exhaust, and spark plug holes.

Now, let's put it back together to see what occurs.

I created a model to get things going right now. We will repair the engine along with all the other parts, such as the gasoline tank.

We need a battery, as we require electricity to accomplish this.

The ignition system, which the engine also brought, is another item. There is one for each rotor. Both arrived with the heat shrink, but I removed one so you could see the ignition system's entire circuitry.

The 'pacifier' that fits into the engine spark plugs is shown there. And yes, we will put the model together rapidly.

Now, we are going to add the coolant and load it with fuel, which contains around 20% nitro.