Steam Turbines, Diesel and Wood Powered Generators, Electric Vibration Motors

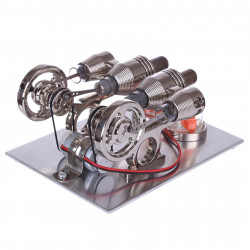

Generators, electric and vibration motors, pumps, steam engines, and steam turbines are examples of power machines.

Beginning as a tiny business producing steam turbines, diesel generators, electric motors, and vibration motors in 1961, EMS has grown to become a prominent worldwide provider of electronic goods for many markets. Pursuing excellence has led to the business's diversification, including adding electric motor goods that offer power generation and more effective ways to use them.

EMS Power Machines

Electric motors remain one of EMS's primary products after over 50 years of existence and continuous expansion. In line with the market, EMS constantly develops its product portfolio, considering each application's unique characteristics. This diversification has been a strong foundation for the company's growth, allowing it to offer more comprehensive solutions and currently serve its customers in a dedicated manner.

This easy and objective guide was produced to aid individuals who buy, sell, and work with such equipment to offer the basis for the success of EMS Motors. It provides crucial data for the functioning of different kinds of motors.

We manufacture vibration motors, AC and DC electric motors, diesel generators, small-scale steam turbines, and marine steam engines.

Diesel Generators as Power Machines

A generator that runs on a diesel engine is known as a diesel generator. Applications for diesel generators are numerous and include:

Diesel generators are frequently used as backup power sources during power outages and in isolated locations without access to the electrical grid.

Primary power: Diesel generators can also serve as the primary power source in places like mining camps and construction sites without access to the electrical grid.

Mobile power: Diesel generators are perfect for mobile power applications like emergency response and disaster assistance since they can be installed on trucks or trailers.

Diesel generators come in various sizes, from compact portable generators that can run a few appliances to massive industrial generators that can power entire buildings.

One dependable and effective power source is a diesel generator. Additionally, they are reasonably simple to maintain.

The following are some advantages of diesel generator use:

Diesel generators are incredibly dependable devices. They can function flawlessly for extended periods.

Efficiency: Diesel generators operate with remarkable efficiency. They can generate electricity from a significant portion of the fuel's energy.

Sturdiness: Diesel generators are incredibly robust devices. They are resilient to challenging working circumstances.

Versatility: Diesel generators are suitable for various uses, including mobile power, primary power, and backup power.

Diesel generators are necessary tools for many organizations and businesses. They offer a dependable and effective power source in various circumstances.

Examples of applications for diesel generators include the following:

Hospitals: In the event of a power loss, hospitals rely on diesel generators as backup power sources. This guarantees the continued operation of vital medical equipment.

Data centres: To safeguard sensitive data, data centres use diesel generators as backup power sources.

Construction sites: To power tools and equipment, construction sites employ diesel generators.

Diesel generators are used in mining camps to power equipment such as lighting and heaters.

Emergency response: Emergency response teams rely on diesel generators to power communication devices, illumination, and other life-saving equipment.

Diesel generators are essential to modern civilization. They offer a dependable and effective power source in a range of circumstances.

We produce diesel generators with the following engine options, ranging from 15 kVa to 2250 KVa:

Perkins Engines

Cummins Engines

Ricardo Engines

Baudoin Engines

Shanghai Dongfeng Engines

Volvo Engines

Yangdong Engines

One backup power source is a diesel generator, which produces electricity using a diesel engine. They are frequently utilized in residential locations where power outages are frequent and in commercial and industrial settings.

Diesel generators function by using an engine to transform diesel fuel into mechanical energy. The engine then turns an alternator to generate electricity. The size and capacity of the engine and alternator determine how much electricity the generator can produce.

Diesel generators offer several benefits. First, diesel fuel can generate greater power per unit of fuel and is more efficient than gasoline. As a result, diesel generators are ultimately more economical. Second, compared to other generator types, diesel generators are more dependable and require less upkeep. Lastly, diesel generators are more robust and have a longer operating lifespan.

Diesel generators are available in various sizes and capacities to accommodate multiple power requirements. Larger diesel generators can power whole buildings or industrial complexes, whereas smaller ones can power a single appliance or a small house. Specific diesel generators are lightweight and portable, making them easy to move to other sites.

Several criteria should be taken into account when choosing a diesel generator. The generator's power capacity is the first. The power required to operate the necessary appliances or equipment should be the basis. The generator's run time is the second factor. How long the generator can run before needing to be refuelled will depend on this. The generator's noise level is the third consideration. Because diesel generators might be noisy, choosing one suitable for the area it will be utilized is critical.

Diesel generators are utilized not just as backup power sources but also in isolated locations with limited or nonexistent access to electricity. They are frequently used in mining operations, building sites, and other industrial environments where electricity is required but not always accessible.

Diesel generators are versatile backup power sources that are economical, dependable, and effective. With the proper upkeep and attention, they offer years of reliable service and comfort during emergencies and power outages.

Engine

Heavy-duty diesel engines made by Ricardo, Cummins, Perkins, Baudoin, Shanghai Dongfeng, Volvo, or Yangdong

Starter and charge alternator 12V/24V

Oil, gasoline, and air filters that are interchangeable

Control of a mechanical governor

Tropical radiator

Flexible fuel hose

An extension hose with an oil drain valve

Steel compensator and industrial-style silencer

Starter battery that requires no maintenance

Heater with water jacket

Engine speed: 1500 rpm

Alternator

Protection Standard IP 21-23

Class H Insulation

The frequency is 50 Hz

Four-pole synchronous brushless alternator

AVR, or automatic voltage regulator

1500 rpm and 400/230V AC output voltage

Soundproof Chassis and Canopy

Easy lifting and transport thanks to its practical design

Superior design for a soundproof canopy

Modular construction with fast-removable nuts and bolts

Doors that can be locked

Clear window to view the Control Panel

Electrostatic powder painting offers a defence against inclement weather

Button for emergency stop

The chassis's internal fuel tank

The engine-chassis and chassis-ground anti-vibration wedges

Optional

For automatic models, thermal magnetic CB

Extremely Silent Canopy

Portable Generator Sets

Fuel-filling mechanism that operates automatically

Panel for synchronization

ATS (Automatic Transfer Switch) with three and four poles

Heaters for fuel and oil

Automatic gasoline filling system and external fuel tank

filter for fuel-water separation

System for remote monitoring and control

Our customers receive generators that are ready to use, with the battery charged and engine oil and antifreeze fluid supplied. Once the electrical connections and exhaust system have been completed under the supervision of authorized personnel, the generator can be used immediately after refuelling. The example below shows that your generator's information is disclosed on the product label. The product label can be found on either the soundproof canopy of the canopied generator or the automatic control panel that opens the generator.

Steam Engines

A steam engine is a heat engine that uses steam as its working fluid to accomplish mechanical work. The steam engine pushes a piston back and forth inside a cylinder using the force created by steam pressure. A connecting rod and crank can convert this pushing power into a rotational force for work.

Steam engines were created in the UK early in the 19th century. They were utilized for railroad transportation until the mid-1900s. They were also employed for many other purposes, including powering sawmills, factories, and ships.

Steam engines are external combustion engines that separate the working fluid from the combustion products. The ideal thermodynamic cycle used to analyze this process is the Rankine cycle.

Rotating and reciprocating steam engines are the two primary varieties of steam engines.

The most prevalent kind of steam engine is the reciprocating steam engine. They function by moving back and forth inside a cylinder with the help of a piston. A crankshaft is turned by the piston being pushed back and forth by the steam pressure.

In rotary steam engines, a revolving rotor circulates steam within a chamber. The rotor turns a crankshaft, pushed around by the steam pressure.

Due to their power and versatility, steam engines have been employed for various purposes over the years. Although less prevalent, they are utilized in multiple devices, such as steam locomotives and power plants.

Examples of steam engines include the following:

Steam locomotives have propelled trains for over a century and are still used in certain regions today.

Steam turbines: Power plants use steam turbines to produce electricity. Some ships and submarines also use them.

Beam engines: In the 1800s, factories were powered by beam engines. Although they are no longer widely utilized, museums nonetheless display specific examples.

Although they are less prevalent than reciprocating steam engines, rotary steam engines are utilized in several settings, including steam automobiles and power plants.

The steam engine is an intriguing and significant aspect of the history of technology. It was essential to the growth of contemporary society and helped drive the Industrial Revolution.

A steam engine is an apparatus that transforms steam's thermal energy into mechanical energy. During the Industrial Revolution, steam engines were employed for many things, such as powering ships, factories, and locomotives.

The steam pressure in a steam engine pushes a piston in a cylinder up and down. The crankshaft, to which the piston is attached, rotates with the piston. The crankshaft can power other devices, like a locomotive wheel or a generator.

High-pressure and atmospheric steam engines are the two primary varieties of steam engines.

The first kind of steam engine to be created was an atmospheric steam engine. These are operated by pushing a piston down in a cylinder with atmospheric pressure, drawing the piston back up in the cylinder. Due to their relative inefficiency, high-pressure steam engines gradually replaced atmospheric steam engines.

Because high-pressure steam engines employed the steam's pressure to force the piston up and down in the cylinder, they were more efficient than atmospheric steam engines. In addition to being more potent than atmospheric steam engines, high-pressure steam engines could power a more excellent range of devices.

Steam engines were essential during the Industrial Revolution. They powered ships, factories, and locomotives, enabling long-distance transportation and large-scale product production. Steam engines also improved people's quality of life by offering a more dependable electricity supply for heating and lighting.

The following are some advantages of steam engines:

Efficiency: Steam engines operate with remarkable efficiency. A significant portion of the fuel's energy can be transformed into mechanical energy by them.

Dependability: Steam engines are incredibly dependable devices. They can function flawlessly for extended periods.

Durability: Steam engines are incredibly resilient devices. They are resilient to challenging working circumstances.

Versatility: Steam engines can power ships, factories, and locomotives, among other things.

Although they are no longer often used, steam engines were essential to advancing contemporary technology. They enabled us to use the many advantages of modern living and contributed to the Industrial Revolution.

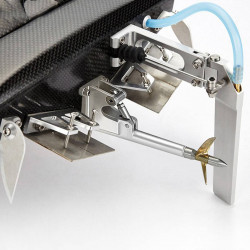

We produce steam launch engines for wooden boats and other maritime vessels.

Small boat steam engines are an excellent choice for anyone looking for a dependable and environmentally responsible way to power their watercraft. These engines create mechanical energy that powers a boat's propeller by heating water using steam from an external source, such as coal, wood, or oil. Despite being used for over 200 years, steam engines are still a standard option for small-boat power today.

You can choose the ideal steam engine for your tiny boat because they are available in various sizes and combinations. Small boat steam engines typically have between 5 and 20 horsepower, while some can reach 100 horsepower. The weight and dimensions of your boat, along with the desired speed, will determine the engine size you require.

Steam Engine Application Areas

Throughout the Industrial Revolution and beyond, steam engines found extensive use. Here are a few instances:

Transportation: Steam engines propelled trains, ships, and steamboats. Early autos and streetcars also used them.

Manufacturing: Steam engines powered textile mills, sawmills, and metalworking shops, among other industry machinery.

Mining: Pumps and other equipment in mines were powered by steam engines.

Agriculture: Cotton gins, threshing machines, and other farm equipment were powered by steam engines.

Power generation: In power plants, electricity is produced by steam engines.

Power plants, steam trains, and steam turbines are just a few of the modern-day uses for steam engines. However, newer engine types like electric motors and internal combustion engines have mostly superseded them.

Here are some particular instances of the various uses for steam engines:

Steam locomotives: Steam locomotives were the main form of rail transit for more than a century. They moved passengers and cargo on railroads.

Steam turbines: Power plants use steam turbines to produce electricity. Some ships and submarines also use them.

Beam engines: In the 1800s, factories were powered by beam engines. They were usually employed to power huge machinery like sawmills and textile mills.

Although they are less prevalent than reciprocating steam engines, rotary steam engines are utilized in several settings, including steam automobiles and power plants.

Steam engines significantly influenced the development of contemporary society. They enabled the long-distance movement of people and products and contributed to the Industrial Revolution.

Steam Turbines

A steam turbine is a device that transforms steam's thermal energy into mechanical energy. It has numerous applications, including powering ships, compressors, and pumps and producing energy.

In a steam turbine, pressure pushes blades onto a rotor. A shaft that rotates in tandem with the rotor is attached to it. The shaft can then power other machines.

Reaction turbines and impulse turbines are the two primary categories of steam turbines.

Reaction turbines move the rotor blades by the expanding force of steam. They are usually employed when high efficiency is needed.

Impulse turbines move the rotor blades by the force of steam jets. They are usually employed in situations requiring a lot of power.

Steam turbines are an essential component of our contemporary infrastructure. They power ships, produce electricity, and power various industrial equipment.

The following are some advantages of steam turbine use:

Efficiency: Steam turbines operate with remarkable efficiency. They can transform a significant portion of the fuel's energy into mechanical energy.

Reliability: Steam turbines are extremely dependable devices. They have no issues and can run for extended periods.

Sturdiness: Steam turbines are incredibly robust devices. They are resilient to challenging working circumstances.

Scalability: Steam turbines can be constructed in various sizes, ranging from tiny industrial turbines to massive power plants. They are, therefore, a flexible and adaptive technology.

In today's world, steam turbines are essential. They supply us with the electricity required to run our businesses, industries, and residences.

The steam turbine is one of the primary energy sources in industries with a need for power and a heat source.

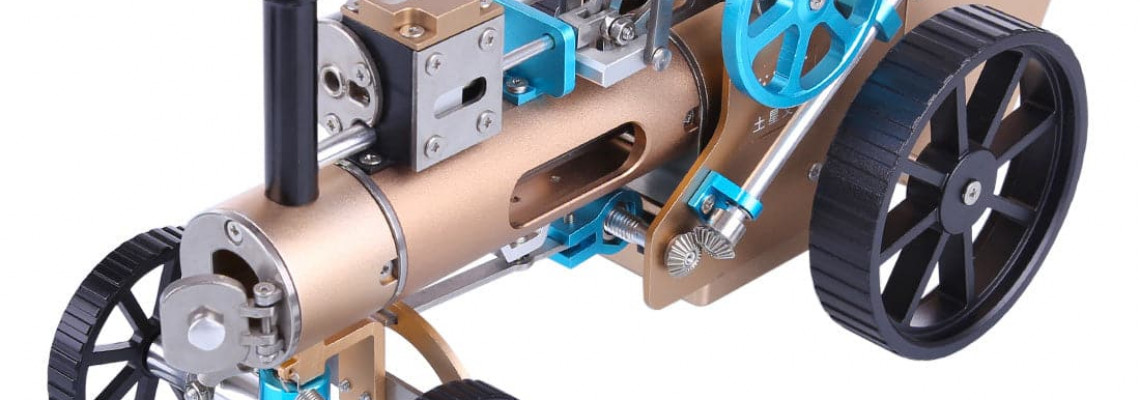

Compact steam turbines have numerous applications, including mechanical drives in industrial machinery and power generation in small-scale power plants. A steam turbine is a device that transforms steam's thermal energy into mechanical energy. Power from small steam turbines usually ranges from a few kilowatts to many megawatts.

Small steam turbines are usually designed with multiple stages of blades that expand steam to provide rotational force. Usually mounted on bearings, the steam turbine rotor revolves on a shaft. The turbine's rotor rotates because the nozzle directs the steam onto the blades. The rotating force is transferred to a generator or apparatus to generate mechanical power or electricity.

Types of Steam Turbines

Impulse turbines and reaction turbines are the two primary varieties of steam turbines.

Impulse turbines

Impulse turbines move their rotor blades by the force of steam jets, which are focused upon them by nozzles. They are commonly employed in power plants and marine propulsion, among other applications where high power is needed.

Reaction turbines

Reaction turbines move their rotor blades by the expanding force of steam. As the steam travels through the turbine, it expands, spinning the blades. Reaction turbines are commonly employed in industrial settings and combined-cycle power plants, among other applications where excellent efficiency is necessary.

In addition to these two primary types, numerous steam turbines are employed in specific applications. These consist of:

Back-pressure turbines: These devices produce steam for process heating and other industrial uses in addition to power.

Extraction turbines: Extraction turbines are used in process heating and other industrial settings to produce energy and extract steam at various pressures.

Condensing turbines: These devices condense steam into a liquid form and produce power.

Reheat turbines: By reheating the steam in between turbine stages, reheat turbines produce power.

Steam turbines are an integral component of our contemporary infrastructure. They power ships, produce electricity, and power various industrial equipment. Steam turbines also have numerous other uses, including district heating and desalination.

Examples of applications for steam turbines include the following:

Electricity production: Steam turbines produce electricity in thermal, combined-cycle, and nuclear power plants.

Marine propulsion: Ships and submarines are propelled by steam turbines.

Applications in industry: Steam turbines power compressors, pumps, and other equipment in various sectors, including petrochemicals, papermaking, and oil and gas.

Desalination: Plants that turn saltwater into freshwater are powered by steam turbines.

District heating: District heating systems powered by steam turbines heat homes and businesses in the surrounding area.

Steam turbines are essential in today's world. They provide the heat, power, and energy required to run our homes, companies, and industries.

Impulse Turbines

Impulse turbines are a kind of steam turbine in which the force of steam jets moves the rotor blades. The blades rotate because the steam jets are focused upon them by nozzles. Impulse turbines are commonly employed in power plants and marine propulsion, among other applications where high power is needed.

Information about impulse turbines' technical aspects:

Nozzles: An impulse turbine's nozzles transform the steam's pressure energy into kinetic energy. Usually, the nozzles have a narrowing section followed by an expanding section, making them convergent-divergent nozzles. This form aids in generating a high-velocity jet and speeding up the steam.

Rotor blades: An impulse turbine's rotor blades are usually shaped like buckets. The buckets are intended to transform kinetic energy into rotational energy by capturing the steam jet. Typically, the blades are composed of a robust and long-lasting substance, such as titanium or stainless steel.

Casing: The impulse turbine's casing keeps the steam contained and prevents it from escaping. The case also supports the rotor and bearings.

Impulse turbine benefits:

High power output: Impulse turbines can provide a high power output, making them perfect for uses requiring high power, such as marine propulsion and power plants.

Simple design: Their straightforward construction makes impulse turbines easy to produce and maintain.

Sturdy construction: Impulse turbines are usually composed of intense and long-lasting materials, making them resistant to deterioration.

Negative aspects of impulse turbines:

Reduced efficiency: Reaction turbines are generally more efficient than impulse turbines. This is because some of the steam's energy is wasted when the jets of steam do not ultimately expand into the turbine.

Increased noise levels: The effect of the steam jets on the rotor blades can make impulse turbines noisy.

Applications of impulse turbines:

Power generation: Thermal power plants employ impulse turbines to produce electricity.

Marine propulsion: Ships and submarines are powered by impulse turbines.

Industrial uses: Impulse turbines power compressors, pumps, and other equipment in various sectors, including petrochemicals, papermaking, and oil and gas.

Inspiring turbine examples include:

Pelton turbine: Hydroelectric power stations use this particular kind of impulse turbine.

De Laval turbine: Originally employed in steam turbines, the De Laval turbine is an impulse turbine.

Curtis turbine: This impulse turbine is employed in several industrial settings and for maritime propulsion.

Impulse turbines are dependable and adaptable, and they are used in many different fields. They are especially well-suited for maritime propulsion and power plants where great power is needed.

Reaction Turbines

One kind of steam turbine is a reaction turbine, which moves its rotor blades using the expanding force of steam. As the steam travels through the turbine, it expands, spinning the blades. Reaction turbines are commonly employed in industrial settings and combined cycle power plants, among other applications where excellent efficiency is necessary.

Reaction turbine technical details:

Nozzles: A reaction turbine's nozzles guide steam into the turbine to optimize efficiency. Usually, the nozzles have a narrowing section followed by an expanding section, making them convergent-divergent nozzles. This form aids in generating a high-velocity jet and speeding up the steam.

Rotor blades: A response turbine's rotor blades are usually fashioned like wings. The wings transform the steam's pressure energy into rotational energy. The blades typically comprise a robust, long-lasting substance, such as titanium or stainless steel.

Casing: The casing of a reaction turbine keeps the steam contained and prevents it from escaping. The case also supports the rotor and bearings.

Reaction turbine benefits include:

High efficiency: In general, reaction turbines outperform impulse turbines in terms of efficiency. This is because more of the steam's energy is transformed into rotational energy when it expands through the turbine.

Reduced noise: Compared to impulse turbines, reaction turbines are usually quieter. This is due to the steam's slow expansion through the turbine rather than its impact on the rotor blades.

More excellent operating range: Compared to impulse turbines, reaction turbines can operate across a more fantastic range of loads and speeds. They are, therefore, more flexible and able to adjust to various working environments.

The following are reaction turbine drawbacks:

Reduced power output: In general, reaction turbines cannot generate as much power as impulse turbines. This is because the steam expands through the turbine, resulting in a lower steam pressure at the turbine's outlet.

More intricate design: Reaction turbines are more intricately designed than impulse turbines. Because of this, they are more costly and challenging to produce and maintain.

Reaction turbine applications include:

Power generation: Some thermal and combined cycle power plants use reaction turbines to produce energy.

Applications in industry: Reaction turbines power compressors, pumps, and other equipment in various sectors, including petrochemicals, papermaking, and oil and gas.

Reaction turbine examples include:

Francis turbine: Hydroelectric power stations employ this particular type of reaction turbine.

Kaplan turbine: Another kind of reaction turbine found in hydroelectric power facilities is the Kaplan turbine.

Axial-flow reaction turbine: This type of reaction turbine is used in industrial settings and combined cycle power plants.

Reaction turbines are an effective and adaptable type of turbine used in many fields. They are especially well-suited for industrial and combined cycle power plant applications where excellent efficiency is necessary.

I hope this further knowledge is helpful. If you have any more queries, do let me know.

Steam Turbine Generation Setups

Using steam's thermal energy, steam turbine generation setups—also referred to as steam power plants—are used to produce electricity. The following elements make up a steam power plant's basic configuration:

Boiler: The boiler generates steam by heating water. The steam turbine then receives the steam.

Steam turbine: This device transforms steam's thermal energy into mechanical energy. The mechanical energy then powers a generator to create electricity.

Generator: The generator transforms the steam turbine's mechanical energy into electrical energy.

Condenser: Following passage through the steam turbine, the steam is condensed in the condenser. As a result, the steam can be recycled and put back into the boiler to produce power.

Along with these fundamental elements, steam power plants usually additionally have a variety of additional parts, including:

Feedwater pumps: These devices return water from the condenser to the boiler.

Superheaters: Before the steam enters the turbine, the superheaters raise their temperature, contributing to the steam turbine's increased efficiency.

Reheaters: The reheaters reheat the steam following a certain number of steps in the steam turbine, which increases the steam turbine's efficiency.

Air preheaters: These devices warm the air used in the boiler to burn the fuel, contributing to the boiler's increased efficiency.

Condensing and non-condensing turbines are the two primary steam turbine generation systems categories.

The condensing turbine is the most prevalent kind of steam turbine seen in power plants. Compared to non-condensing turbines, condensing turbines run at a lower pressure. This allows the steam to condense after passing through the steam turbine. The condensed steam is then reintroduced into the boiler to produce more power.

Non-condensing turbines run at more significant pressure than condensing turbines. Because of this, the steam cannot condense after passing through the steam turbine. The exhaust steam from a non-condensing turbine is also used for district and process heating.

Steam turbine generation systems are an effective and dependable method of producing electricity. Power plants, industrial facilities, and commercial structures are just a few of their many uses.

Here are some examples of steam turbine generation setups:

Thermal power plants: These facilities burn fossil fuels like coal, natural gas, and oil to produce electricity using steam turbines.

Nuclear power plants: Nuclear power plants use the heat from nuclear fission to power steam turbines.

Combined cycle power plants: These facilities produce energy using gas and steam turbines. After the gas turbine generates power, the steam turbine harnesses the heat from the exhaust gases to create steam.

Industrial facilities: Steam turbines are employed in various industrial facilities to produce power for on-site consumption.

Business buildings: Some business buildings, such as data centres and hospitals, use steam turbines to provide electricity for on-site consumption.

Steam turbine generation systems are crucial to the modern world because they provide a dependable and adequate electricity supply.

Wood Powered Generators

A technique known as a wood gasifier electric generator uses the energy released while burning biomass or wood to create electricity. This novel technology uses a gasification process to turn solid wood or other organic materials into Syngas, a flammable gas. Syngas, a blend of hydrogen, carbon monoxide, and other trace gases, can power an internal combustion engine coupled to a generator.

Wood or biomass is fed into the gasifier unit to start the wood gasification process. This device, usually a reactor or chamber, works in an oxygen-poor atmosphere, inhibiting complete combustion and encouraging the creation of Syngas. The thermochemical reactions during gasification break down wood's complex organic molecules, yielding volatile gases that can be used as fuel.

One of the benefits of wood gasifier electric generators is the utilization of wood, a plentiful and renewable resource. Wood is a sustainable and carbon-neutral fuel source because the carbon absorbed by the trees during their growth balances the carbon dioxide emitted after combustion. Because of this, wood gasification is a more environmentally friendly alternative to conventional fossil fuels.

After that, the generated Syngas are sent to an internal combustion engine connected to an electric generator. This engine is often a modified gasoline or diesel engine. When the engine burns the Syngas, the chemical energy is transformed into mechanical energy, powers the generator and generates electricity. A decentralized and dependable energy source, the generated power can power homes, businesses, or off-grid sites.

Wood Gasifier Electric Generator

Electric generators powered by wood gasifiers are used in various locations, such as rural and isolated regions where conventional power lines may not be easily accessible or feasible. In areas with a wealth of biomass resources, these systems provide a practical option for off-grid living, emergency backup power, or sustainable energy.

Wood gasifier electric generators have drawbacks despite their benefits. Careful feedstock preparation is necessary since the gasification process might be sensitive to the kind and moisture content of the biomass. Furthermore, the quality and design of the engine and gasifier unit may impact the system's power production and efficiency.

To sum up, wood gasifier electric generators, which harness the energy potential of biomass to generate electricity, offer a flexible and sustainable approach to localized power generation. Thanks to continuous technological improvements and growing awareness of renewable energy sources, wood gasification systems are developed and adopted as a cleaner and more ecologically friendly energy alternative despite obstacles.

Wood gasification turns solid biomass, like wood, into Syngas, a gaseous fuel. This thermochemical reaction occurs in a gasifier, which functions in an atmosphere with low oxygen levels. When wood is heated during the gasification process, the absence of oxygen inhibits complete combustion, creating Syngas. The potential for this adaptable energy source to offer a sustainable substitute for conventional fossil fuels has drawn attention.

There are several essential steps in the gasification of wood. First, biomass is fed into the gasifier, usually as pellets or wood chips. Heat within the gasifier starts a chemical reaction chain that breaks down the wood's complex organic constituents. As a result, Syngas—which is composed of volatile gases such as carbon monoxide, hydrogen, and methane—is released.

The generated Syngas can be used for several purposes, but one popular one is fuel for internal combustion engines connected to generators. Thanks to this method, wood can now be used to generate electricity, making it an environmentally benign and renewable energy source. Wood gasification is incredibly alluring as a sustainable substitute for traditional power sources in areas with a wealth of biomass resources.

Wood gasification technology is still being researched and developed to increase efficiency, lower emissions, and broaden the spectrum of suitable feedstocks. Wood gasification is an essential renewable energy option that helps create a more sustainable and greener future by reducing reliance on non-renewable energy sources and mitigating climate change.

Syngas

Syngas, a synthesis gas, is a multipurpose fuel made by gasifying carbon-containing sources like coal or biomass. Carbon monoxide (CO) and hydrogen (H2) make up the majority of this gaseous combination, while it also frequently contains trace amounts of methane (CH4) and other gases. Syngas have become well-known as a valuable intermediate product with several uses, such as producing power, synthesizing chemicals, and serving as a biofuel precursor.

Carbon-rich feedstocks are usually heated to high temperatures in a gasifier or controlled environment with little oxygen to produce Syngas. During this thermochemical process, the biomass is subjected to pyrolysis, gasification, and reforming reactions, which release the volatile components that make up Syngas.

One of Syngas's main benefits is its versatility as a fuel. It can be used as a substitute for conventional fossil fuels in internal combustion engines to produce electricity. Furthermore, using a process called Fischer-Tropsch synthesis, Syngas is used as a feedstock to create liquid biofuels like synthetic gasoline or diesel.

Additionally, Syngas are used in industrial activities, such as synthesizing compounds like methanol and ammonia. Syngas can be adapted to various uses by changing their composition according to particular needs. Its manufacturing from renewable biomass resources also helps create a more ecologically friendly and sustainable energy landscape.

This adaptable fuel has the potential to solve energy issues, support cleaner energy sources, and lower greenhouse gas emissions linked to conventional fossil fuels as long as gasification technology and syngas use continue to progress. Continuous research and development in its uses highlight Syngas's potential to be a key component of the shift to a more sustainable energy future.

Electric Motors

Electric motors are devices that transform electrical energy into mechanical energy. They are used in power tools, appliances, industrial machines, and automobiles.

Electric motors operate by the magnetic force between a current-carrying wire and a magnetic field. When current passes through a conductor, a magnetic field surrounds it. When an external magnetic field is applied to a conductor, the two fields interact and exert force on the conductor. This force can rotate a shaft and power further devices.

AC motors and DC motors are the two primary varieties of electric motors.

The power source for AC motors is alternating current. Typically, AC motors are found in high-power devices like industrial appliances and machines. Two popular kinds of AC motors are synchronous and induction motors.

Direct current (DC) powers DC motors. Low-power equipment like power tools and battery-operated gadgets are common uses for DC motors. Two popular varieties of DC motors are DC brushed motors and DC brushless motors.

Electric motors are divided into various categories based on construction and operation principles. The following are a few of the most popular kinds of electric motors:

Induction motors: Induction motors are the most prevalent AC motors. Designing and manufacturing induction motors is straightforward, and they are reasonably priced.

Synchronous motors: These AC motors run steadily under synchronous conditions. They are used in applications requiring precise speed control, including clocks and generators.

DC brushed motors: The most popular DC motor is the DC brushed motor. In addition to being reasonably priced, DC brushed motors are easy to design and produce.

DC brushless motors: These are a particular kind of brushless DC motor. Compared to DC brushed motors, DC brushless motors are more dependable and efficient but cost more.

Electric motors are a necessary component of contemporary living. They are essential to our economy and way of life and are utilized in various gadgets and applications.

Here are a few electric motor examples:

The blender's engine that mixes your drinks

The vacuum cleaner's motor that cleans your floors

The washing machine's motor, which cleans your clothes

The vehicle's motor, which drives it forward

The air-circulating fan's motor

The screw-driver motor of a power drill

Electric motors are ubiquitous and contribute to the convenience and ease of our lives.

Apart from the instances above, electric motors are employed in several industrial settings, including:

Manufacturing: Electric motors power various manufacturing machinery, including robots, conveyor belts, and machine tools.

Energy: Electric motors drive various renewable energy devices, including solar panels and wind turbines, and produce electricity in power plants.

Transportation: Electric automobiles, buses, and trains are just a few vehicles that use electric motors.

Electric motors are an efficient and adaptable technology that has completely changed our work and life.

For the industry, we produce AC and DC electric motors. Visit our link to learn more.

Electric motors are devices that transform electrical energy into mechanical energy. They are vital to many contemporary technologies and are frequently utilized in various applications, from industrial gear to home appliances.

An electric motor operates on a straightforward concept. It is made up of a conductor and a magnetic field. The interaction between the electric charge and the magnetic field causes the conductor to experience a force when a current is carried through it. The magnetic field's orientation and the current's direction determine the force's direction.

Types of Electric Motors

Electric motors come in a wide variety, each with unique benefits and drawbacks. The following are a few of the most popular kinds of electric motors:

AC motors: AC motors are the most prevalent electric motor worldwide. They are powered by alternating current (AC) and are commonly found in high-power applications like industrial appliances and machinery. Common AC motor types include synchronous and induction motors.

DC motors are usually found in low-power applications like power tools and battery-operated gadgets. They are driven by direct current (DC). Two popular varieties of DC motors are DC brushed motors and DC brushless motors.

A more thorough rundown of some of the most popular kinds of electric motors can be found here:

Induction motors: The most basic and prevalent AC motor is the induction motor. They are less efficient but reasonably priced and easier to maintain than other motor types. Induction motors are frequently found in industrial settings in compressors, fans, and pumps.

Synchronous motors: These AC motors run steadily under synchronous conditions. This makes them perfect for devices like clocks and generators that need precise speed control. Although synchronous motors are more efficient than induction motors, they are usually more costly.

DC brushed motors: The most popular DC motor is the DC brushed motor. Although they are easy to manage and reasonably priced, the brushes necessitate frequent upkeep. Battery-operated devices and power equipment frequently use DC brushed motors.

DC brushless motors: These are a particular kind of brushless DC motor. Because of this, they are more dependable and efficient than DC brushed motors, although they cost more. Electric vehicles and drones are two high-performance applications that frequently use DC brushless motors.

Numerous varieties of electric motors are available in addition to the ones mentioned above, each with unique qualities and uses. Other electric motor examples are as follows:

Stepper motors: Stepper motors are electric motors that may be operated with extreme precision. Because of this, they are perfect for devices like 3D printers and CNC machines that need exact placement.

Servo motors: These motors may be precisely manipulated to move to a desired position. Because of this, they are perfect for applications like industrial automation systems and robotic arms that need accurate position and speed control.

Linear motors: Rather than producing a rotating force, linear motors generate a linear force. This makes them perfect for devices like conveyors and elevators that need linear motion.

Electric motors are a necessary component of contemporary living. Power tools, industrial machines, and electric cars are just a few of the many uses for them. You can select the ideal electric motor for your requirements by being aware of the many kinds of motors and their uses.

Power Outputs of Electric Motors

The quantity of mechanical power an electric motor can generate is known as its output. Watts (W) or horsepower (HP) are used to measure it. An electric motor's size, design, and operating circumstances are some of the variables that affect its power output.

Small electric motors, such as those used in power tools and appliances, typically have power outputs ranging from a few watts to a few kilowatts (kW). Large electric motors, such as those used in industrial machinery and electric vehicles, can have power outputs ranging from hundreds of kilowatts to megawatts (MW).

Operating conditions also impact an electric motor's power output. For instance, if an electric motor runs faster, it will generate more power. However, as the speed rises, the motor's efficiency will fall.

Examples of the power outputs of several electric motor types are as follows:

Drill motor power: 100–500 W

Motor for washing machine: 500–1000 W

Motor for vacuum cleaner: 1000–2000 W

Motor for air conditioner: 2000–3000 W

Motor for an electric vehicle: 100–200 kW

Industrial motor: between 100 kW and 1 MW

It is crucial to remember that an electric motor's efficiency and power output are not the same. An electric motor's efficiency is the proportion of electrical power input transformed into mechanical power output. Electric motors with higher efficiency will provide more mechanical power output for a given quantity of electrical power input.

Electric motors are a necessary component of contemporary life. They are used in power tools, industrial machines, and electric cars. The power output of an electric motor is a key factor to consider when choosing a motor for a particular application.

Vibration Motors

Electromechanical devices, known as vibration motors, transform electrical energy into mechanical vibration. They are employed in numerous applications, such as:

Mobile devices: Mobile gadgets like smartphones and tablets use vibration motors to give the user haptic input. These motors can show when a notification has been received or when a button has been pressed.

Video game controllers: Video game controllers use vibration motors to give the player a haptic sensation. This can replicate sensations such as the sound of a gunshot or the sensation of operating a motor vehicle.

Medical equipment: To deliver therapeutic vibration, various medical products, such as massage chairs and toothbrushes, use vibration motors.

Industrial uses: Vibration motors are used in many industrial applications, including conveyor belts and vibrating feeders.

Linear resonant actuators (LRAs) and eccentric rotating mass (ERM) motors are the two primary categories of vibration motors.

The most basic kind of vibration motor is an ERM motor. They generate vibration using a revolving eccentric mass. Although ERM motors are easy to make and reasonably priced, their efficiency is inferior to that of LRAs.

LRAs are a more recent form of vibration motor. They are more efficient and capable of producing more vibration than ERM motors. LRAs generate vibration using a resonant frequency. Although LRAs are more costly than ERM motors, high-end electronics increasingly use them.

Vibration motors are a vital component of many contemporary electronics. They give users haptic feedback, which can improve the usability and enjoyment of electronics.

Here are a few vibration motor examples:

When you receive a notification, your smartphone's vibration motor vibrates.

Your video game controller's vibration motor vibrates when you hit a bump or fire a gun.

Your massage chair's vibration motor, which produces healing vibration

Your electric toothbrush's vibration motor, which aids in plaque removal

There are vibration motors everywhere, and they add convenience and enjoyment to our lives.

We produce vibration motors in a range of sizes and for a variety of applications. See the aforementioned link for additional details.

Compact electric motors, known as vibration motors, are employed in a variety of commercial and industrial settings to produce vibrations. An eccentric weight is fastened to the rotor of these motors. The weight creates a centrifugal force that causes the motor to vibrate as it revolves. Vibration motors can produce different vibrations, including elliptical, circular, and linear vibrations.

Mobile phones, pagers, and other portable electronic gadgets frequently use vibration motors to offer haptic feedback. Vibration motors are also employed in several industrial settings, including vibrating tables, packaging machinery, and conveyor systems. They are also utilized in automobile applications such as engine mounts, seatbelt tensioners, and airbag systems.

Application Areas

There are many different applications for vibration motors, such as:

Mobile devices: Mobile gadgets like smartphones and tablets use vibration motors to give the user haptic input. These motors can show when a notification has been received or when a button has been pressed.

Video game controllers: Video game controllers use vibration motors to give the player a haptic sensation. This can replicate sensations such as the sound of a gunshot or the sensation of operating a motor vehicle.

Medical equipment: To deliver therapeutic vibration, various medical products, such as massage chairs and toothbrushes, use vibration motors.

Industrial uses: Vibration motors are used in many industrial applications, including conveyor belts and vibrating feeders.

Automotive uses: Seat belt tensioners, haptic feedback systems in steering wheels, and gear shifters are just a few examples of automotive applications for vibration motors.

Wearable technology: Vibration motors are used in wearable technology, including fitness trackers and smartwatches, to give users haptic feedback.

There are numerous further uses for vibration motors, including:

Toys: To create stimulation, some toys, such as vibrating balls and sex toys, use vibration motors.

Massage chairs: To produce therapeutic vibration, massage chairs employ vibration motors.

Toothbrushes: Some toothbrushes utilize vibration motors to assist in eliminating plaque.

Appliances: Several appliances, such as dryers and washing machines, use vibration motors to lessen noise and vibration.

Industrial equipment: Conveyors and feeders are two examples of industrial equipment that use vibration motors to move items.

Vibration motors are a versatile and valuable technology that has a wide range of applications.

Here are some particular instances of the various applications for vibration motors:

Cellphone vibration motors enable haptic feedback in response to screen taps; button pushes, and notifications. This feedback may help users engage with their gadgets more successfully and efficiently.

Vibration motors are used in video game controllers to replicate the sensation of various game operations, including shooting a gun, operating a vehicle, or being struck by an adversary. This feedback may make games more engaging and entertaining.

Vibration motors are utilized in massage chairs to give people therapeutic massage. This massage can facilitate relaxation, increase circulation, and ease tense muscles.

Vibration motors in electric toothbrushes help remove plaque from teeth. The vibration loosens plaque, making it easier to wipe away.

Vibration motors are utilized in industrial settings to move goods on feeders and conveyor belts. In addition to facilitating faster and more effective material movement, the vibration helps keep materials from adhering to the feeders and belts.

Types of Vibration Motors

Linear resonant actuators (LRAs) and eccentric rotating mass (ERM) motors are the two primary varieties of vibration motors.

The most basic kind of vibration motor is an ERM motor. They generate vibration using a revolving eccentric mass. Although ERM motors are easy to make and reasonably priced, their efficiency is inferior to that of LRAs.

LRAs are a more recent form of vibration motor. They are more efficient and capable of producing more vibration than ERM motors. LRAs generate vibration by means of a resonant frequency. Although LRAs are more costly than ERM motors, high-end electronics are increasingly using them.

A more thorough comparison of ERM motors and LRAs can be found here:

Feature ERM motor LRA

Operating principle Uses a rotating eccentric mass to create vibration Uses a resonant frequency to create vibration.

Efficiency Less efficient More efficient

Vibration output Lower vibration output Higher vibration output

Cost Less expensive More expensive

Typical applications Mobile devices, video game controllers, toys Mobile devices, high-end video game controllers, wearables

There are a few different kinds of vibration motors besides ERM and LRA motors, including:

Solenoid actuators: These devices generate vibration using a magnetic field. They are usually employed when a strong vibration force is needed.

Piezoelectric actuators: Piezoelectric actuators generate vibration using the piezoelectric effect. They are usually employed in situations requiring exact vibration.

Vibration motors are a practical and adaptable technology with many uses. The individual needs of a given application will determine the most appropriate vibration motor.

Pumps

Pumps are machines that move liquids by transferring energy to the fluid from a power source. Pumps are extensively employed in many different applications, such as:

Treatment of water and wastewater: Pumps transport water and wastewater through distribution networks and treatment facilities.

Power generation: Pumps in power plants move water, steam, and other fluids.

Applications in industry: Pumps transport a wide range of fluids in industries such as manufacturing, food processing, and chemical processing.

Business and residential uses: Pumps are employed in many business and domestic settings, including swimming pools, irrigation systems, and heating and cooling systems.

There are numerous varieties of pumps, and each has pros and cons. Among the most popular kinds of pumps are:

Centrifugal pumps are the most widely used kind of pump. They move fluid through the pump by producing centrifugal force with a revolving impeller. A wide range of fluids can be pumped with centrifugal pumps, which are also reasonably priced and simple to maintain.

Positive displacement pumps: These pumps move fluid through the pump by trapping a volume of fluid and then displacing it. Although positive displacement pumps cost more than centrifugal pumps, they can handle higher pressures and a greater variety of fluids.

Reciprocating pumps: These pumps move fluid through the pump using a plunger or piston. Although reciprocating pumps can produce extremely high pressures, they are also more costly and sophisticated than other pumps.

The kind of fluid being pumped, the necessary flow rate, and the required pressure are some variables that will determine which type of pump is appropriate for a particular application.

Examples of various pump types and their uses are as follows:

Centrifugal pumps: These pumps are frequently utilized in industrial settings, power generation, and water and wastewater treatment.

Positive displacement pumps: These pumps are frequently seen in industrial settings, including manufacturing, food processing, and chemical processing.

Reciprocating pumps are used in unutilized systems, oil and gas production, and other industrial settings.

Pumps are a vital component of contemporary life. They transport fluids between locations in a wide range of applications. By being aware of the many kinds of pumps and their uses, you can select the ideal pump for your requirements.

We produce pumps in various sizes and for a range of applications. See the aforementioned link for additional details.

Electric pumps are machines that use electrical energy to move liquids or gases from one place to another. They are used in water supply, irrigation, drainage, sewage, and chemical processing.

Electric pumps come in various forms, each with special qualities and uses. Axial flow, positive displacement, and centrifugal pumps are a few of the most popular varieties.

Application Areas

There are many different uses for pumps, such as:

Treatment of water and wastewater: Pumps transport water and wastewater through distribution networks and treatment facilities.

Power generation: Pumps in power plants move water, steam, and other fluids.

Applications in industry: Pumps transport a wide range of fluids in industries such as manufacturing, food processing, and chemical processing.

Business and residential uses: Pumps are employed in many business and domestic settings, including swimming pools, irrigation systems, and heating and cooling systems.

Here are a few particular instances of the various uses for pumps:

Pumps transport water from lakes and rivers to treatment facilities, where it is purified before being delivered to residences and commercial buildings. They also transport wastewater from residences and commercial buildings to treatment facilities, where it undergoes treatment before being released back into the environment.

Power generation: Pumps move water, steam, and other fluids in power plants. Pumps, for instance, transport water from lakes and rivers to power plants so that steam can be produced. Additionally, steam is moved by pumps through turbines to produce power.

Applications in industry: Pumps transport a wide range of fluids in sectors, including manufacturing, food processing, and chemical processing. In chemical facilities, for instance, pumps transport chemicals; in food processing plants, they move food products; and in manufacturing plants, they move materials.

Business and residential uses: Pumps are employed in many business and domestic settings, including swimming pools, irrigation systems, and heating and cooling systems. For example, pumps move water to sprinkler heads in swimming pools, irrigation systems, and heating and cooling systems.

Pumps are a vital component of contemporary life. They transport fluids between locations in a wide range of applications. Many of the things we depend on daily would not be possible without pumps.