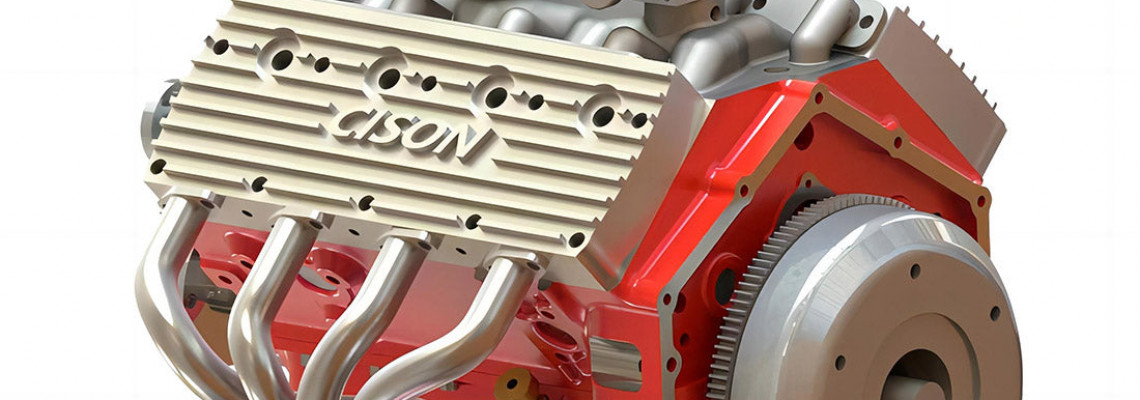

All You Need to Know About CISON FL4-175 Flathead Inline 4 Engine

Igniter CDI

1. Sensor

a. Kindly first open the observation window for the ejector rod and valve.

b. Locate the first cylinder by referring to the image on the CDI.

c. Turn the flywheel counterclockwise and look at cylinder 1's inlet valve. After the inlet valve has been opened, continue turning the flywheel until it reaches the upper dead centre, the first cylinder's compression point. Maintain the flywheel's motion at this point.

d. Attach the coloured CDI magnet to the crankshaft pulley (foam: 27).

The faces Hall magnetic pole

It should be noted that if the magnet installation protrudes, it could clash with the engine screw. (Option 2: include shims in the pulley installation (27))

e. Install the upper belt pulley's fixing screw at this point. Do not adjust the belt pulley, please.

f. The revolving pulley magnet triggers a hall near the water pump. (Note: trigger has a 15–0° advance.)

2. High voltage line

a. Study the images on the CDI, verify the cylinder order, and place the high-voltage wire appropriately.

Remember that the spark plug does not directly contact the high-voltage cable. Please avoid leaving more than 2 mm between the spark plug and the high-voltage cable, which could damage the sensor.

3. Ground wire

a. To guarantee the high voltage, the CDI's black wire must be attached to the engine block.

-voltage circuit. Otherwise, the sensor will be damaged

Before preparing for an operation

Be careful!:

1. The starting motor may overheat and burn if the machine is forced to start without being run in.

2. It is advised to fill the oil pan with 15–18 millilitres of lubricating oil (10w50 suggested for extreme instances).

1. Oil pump adjustment

a. First, make sure the oil pipe is connected appropriately.

b. Kindly screw in the oil flow adjustment.

c. Please modify the oil flow from near to distant (the closer to the oil) by the internal oil pipe.

Pump, the lower the flow should be to prevent the farthest oil hole from drying.)

d. It is advised against initially installing the crankcase side cover (foam Nos. 04, 05). Check for lubricating oil splashes during running in to help with flow correction.

2. The engine resistance will be relatively large Since the new machine has not been run. Please carry out the following operations first

a. Take out the spark plugs.

b. Accurately adjust the oil pump, please

c. Use the DC 6–8 volt power supply for pressure-free running before attaching the beginning motor (note that this step can be skipped if a single piston ring filter is utilized; otherwise, the starting motor cannot run for an extended period).

d. Once everything operates smoothly, replace the two spark plugs and restart the engine. Install the remaining components if the engine is easily operated.

Replace both spark plugs and restart the starter. The cold running in the process is effective if it can be driven quickly. If not, please remove and reinstall the spark plug to continue running in (be careful and pay attention to lubrication during running in; add a tiny amount of lubricating oil to the cylinder liner).

1. Forcibly starting the machine without running it may cause the starting motor to overheat and burn.

2. It is advised to fill the oil pan with 15–18 millilitres of lubricating oil (10w50 suggested for particular instances). Other labels are permitted as well.

Other Questions People Might Ask.

Question 1. How much oil does it need, and what type? I put 36cc 10w40

Reply:

First, the ignition time shouldshould be earlier because the magnet cannot be on the Hall. I'm unsure if the 5–10 advance you mentioned refers to the magnet's advancement based on the Hall or the ignition time advance after returning to 0. I believe wiping the valve should come first. After opening the intake valve, continue turning the flywheel to reveal the spark plug hole, or insert a non-metallic object to feel if the piston has reached the top step or the compression stroke. Alternately, leave other markings, and then screw on the high-pressure igniter cap and spark plug. At this point, remove the pulley's fixing screw and twist it while keeping the crankshaft flywheel stationary until a high-pressure spark that can be repeatedly ignited appears on one cylinder's high-pressure cap. Verified twice that it is a cylinder's spark. The ignition angle is at 0°. The pulley can now be set to retreat 5–10° counterclockwise, equivalent to the angle corresponding to the igniter's advance.

a. Now, secure the pulley so that it does not rotate, lock the pulley screw, and manually turn the flywheel.

b. Verify that the scale before the flywheel matches the ignition time that has been specified.

c. Verify if the pulley is lodged in the Hall mounting screw; occasionally, this can make the pulley slide. The debugging and igniting have been postponed until now.

Second, the intake valve will open after the exhaust is closed and the camshaft is still rotating.

a. The setting is incorrect if not.

a. If so, does the intake valve open as soon as the crankshaft rotates and the piston reaches the top dead centre? It should be adjusted wrongly if the piston descends more than 0.5 mm before it begins to open. Intake valves should be open when the piston lowers more than 0.1mm, and it should be accurate that the intake valve is at the top dead centre.

Third, if circumstances allow, you can replace the Zhongyang 18 carburettor test. The air valve is approximately 1.3mm, the Zhongyang main oil needle is three circles, and the auxiliary oil needle is 0.7 circles. The air valve should be roughly 1.5 mm, the primary oil needle should be 1.3–1.5 circles, and the auxiliary oil needle should be 0.8 if the original carburettor is used.

Fourth, starting with one piston ring is relatively easy, but using two piston rings or O-rings might be easier and more stable. The footage appears to show no evidence of a flaming explosion. Please assist me with these tests.

a. You can use your finger to test the carburettor's suction strength.

a. Determine whether the igniter is normal. If four ignites at the same time on occasion, that is normal; if four ignites at the same time every time, that is abnormal.

c. To check the ignition angle, rotate the flywheel after making a scale on the crankshaft, as I previously mentioned.

d. Carburetor: The Zhongyang 18 carburettor may be more stable, and you are aware of the approximate quantity of oil needle circles, so you might try using it for testing.

Question 2:

Does the Cison FL4-175 have a quadruple crankshaft? Not just two bearings like the Toyon FS-L400.

Reply: The TOYAN L400 and this crankshaft are different. Three points—the middle, the two ends, and the two ends—are where the crankshaft is supported. The copper tile is located in the middle.

Question 3:

Your new engine, cison fl4-175, is interesting; any info other than site info? I like it very much, and this will be my next purchase. I have been waiting to find it in your store since you posted the video on YouTube.

Reply: I'm glad you like it. We are testing a suitable frame and creating the clutch for this engine, which will be invaluable in RC models.

Question 4:

Please What oil filter should I order for my Cison FL4-175? You sent me the accessory kit, but it doesn't include the oil filter. The Cison FL4-175 operating manual states that Cison has a free patch available to start the motor. Can I ask for a reduction ratio (33:1), please?

Reply: yes. I'm glad you like it. We are testing a suitable frame and creating the clutch for this engine, which will be invaluable in RC models.

Question 5: Can I get the replacement part of the Cison FL4-175 engine?

Stirlingkit Reply: yes. You can. Please download the Cison FL4-175 part list file and tell me the series number of the part you want. So i can solve the problem as fast.

Question 6: The pistons, cam, and valves are now installed. I'm preparing to finish the remaining pieces. I need to double-examine the details because there are a few confusing areas in the directions.

Question 7: Is there a downdraft or updraft carburettor? The instructions show the manifold upside down with the carbonator at the bottom (updraft). However, the online photographs and videos show it attached to the top of the manifold (downdraft). Its foundation is an updraft engine.

Reply: We also have intake manifolds fitted downward, independent of suction up or down. The carburettor is a pipe with a control valve. It is devoid of suction itself. The pressure inside the cylinder creates the suction.