What is a 4 stroke engine?

A 4 stroke engine completes the four stages of Suction, Compression, Power, and Exhaust in just two crankshaft revolutions. The vast majority of cars today use four-stroke engines.

First, let's review some fundamental terminology related to 4 stroke engines.

Top dead center (TDC)

It is the piston's extreme position at the cylinder's head end. The crank angle is 0* at TDC.

Bottom dead center (BDC)

The piston's extreme location is on the crank end side. The crank angle is 180* at BDC.

Cylinder bore

It is the cylinder's internal diameter.

Stroke

It is the distance the piston covers in a single stroke inside the cylinder.

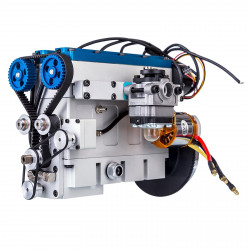

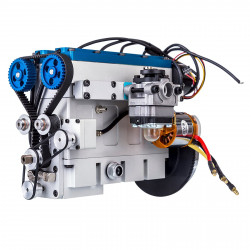

Parts of 4 Stroke engine

The components of a four-stroke engine are as follows:

- Cylinder: It serves as the engine's core. In the cylinder, the piston moves back and forth.

- Cylinder head: The top cap of the cylinder, facing TDC, is referred to as the cylinder head.

- Piston: It is the engine's reciprocating component. The cylinder allows it to reciprocate.

- Piston rings: There are two or three piston rings on the piston. It closes the space between the piston and cylinder lining.

- Crank: It is a member that rotates. It moves inside the crankcase in a circular motion.

- Crankcase: It is the crank housing along with other engine components. It serves as the lubricating oil sump as well.

- Connecting rod: It is employed to change the piston's reciprocating motion into the crankshaft's rotating motion.

- Crankshaft: The component that rotates is what joins the crank.

- Cooling fins or water jackets are used for cooling purposes.

- Cam and Camshaft: It is employed to run the diesel engine's fuel injection pump and to permit the opening and closing of the intake and exhaust valves.

- The inlet valve regulates the engine cylinder's charge or air admittance.

- Exhaust valve: After combustion, the removal of burned gas is managed by this valve.

- Intake manifold: The fresh air or charge is carried by this channel.

- Exhaust manifold: The exhaust gas exits the engine cylinder through this opening.

- Spark plug: It ignites fuel in gasoline or spark ignition engines.

- Fuel injector: It sprays gasoline within the diesel or CI engine cylinder.

- Carburetor: It ensures the fuel and air are correctly mixed in a gasoline engine.

- Flywheel: It is fixed to a crankshaft and composed of cast iron. It has the inertia to store energy.

Classification of 4 stroke engine

The four-stroke engine is generally classified into two types:

- Four-stroke petrol engine

- Four-stroke diesel engine

Let us understand each one in detail.

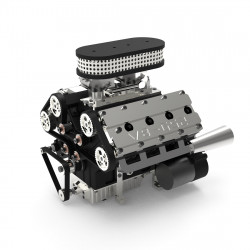

Four-stroke Petrol engine

It is fixed to a crankshaft and composed of cast iron. It has the inertia to store energy.

Construction of Four-stroke Petrol engine

A four-stroke petrol engine consists of the following:

- A cylinder

- The cylinder head attached with a spark plug

- Piston attached to piston ring

- Connecting rod

- Crank

- Crankshaft

- Valves

Engines with four strokes use valves instead of ports. These are the two valves that were used:

- Suction valve

- Exhaust valve

Additionally, the camshaft is used to operate these valves. It revolves at a half-crankshaft speed.

Working principle of the Four-stroke petrol engine

When a piston moves from one dead center to another, it is called a stroke. In a four-stroke cycle, there are four strokes:

- Suction Stroke

- Compression Stroke

- Power or Expansion Stroke

- Exhaust Stroke

Suction stroke

The exhaust valves stay closed throughout this stroke, but the suction valve opens. A partial vacuum inside the engine cylinder causes the piston to move from its top dead center to its bottom dead center, allowing the charge (air and fuel) to enter the cylinder. The flywheel completes a half revolution, and the inlet valve closes when the piston reaches the BDC.

Compression Stroke

The piston travels from BDC to TDC during this stroke. The cylinder's inside air is heated and compressed. Both of the valves are closed during this stroke. The mixture was drawn into the cylinder and crushed into the combustion chamber during the suction stroke.

The mixture is vaporized by the heat generated during the compression stroke. The compression stroke ends as the piston gets closer to the top dead center, at which point the spark plug ignites.

Power Stroke or Expansion stroke

In this stroke, the exhaust and intake valves are closed once more. The vital spark ignites the compressed charge, which then adiabatically expands. To finish the stroke, the piston is forced lower or towards BDC.

Exhaust Stroke

The exhaust valve is opened, and the inlet valve is closed during the exhaust stroke. At BDC, the piston rises to TDC. The stroke is considered complete when the piston reaches the Top Dead Center. In one scenario, during the exhaust stroke, both valves are open briefly to allow new charge to enter the engine cylinder and force the burned gasses out of it. We refer to this procedure as scavenging.

Theoretical valve-timing:

- The Inlet valve opens when the piston is at TDC

- The Inlet valve closes when the piston reaches BDC

- Spark is produced when the piston reaches TDC

- The exhaust valve opens when the piston is at BDC

- The exhaust valve closes when the piston is at TDC

Actual valve-timing:

- The Inlet valve opens about 10°-20° before TDC

- The inlet valve closes 30°-40° after BDC to take advantage of rapidly moving gas

- The spark occurs 20°-35° before TDC

- The exhaust valve opens about 30°-50° before BDC

- The exhaust valve closes about 10°-15° after TDC

Applications of Four-stroke Petrol engine:

The applications of a four-stroke gasoline engine are as follows:

- Automobiles

- 4 stroke engine kit for bike

- Cars

- Buses

- Trucks

- Airplanes

- Small pumping sets

- Mobile electric generator

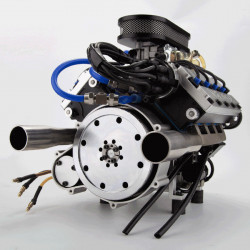

Four-stroke Diesel engine:

Construction:

The components of a diesel engine with four strokes are as follows:

- A fuel injector

- Fuel pump

- Cylinder

- Cylinder head

- Inlet and exhaust valves

- Piston

- Piston ring

- Connecting rod

- Camshaft

- Crankshaft

- Cam

Working principle of Four-stroke Diesel engine:

The four-stroke diesel engine's cycles are identical to the gasoline engine's.

- Suction Stroke

- Compression Stroke

- Power or Expansion Stroke

- Exhaust Stroke

Suction Stroke:

The exhaust valve stays closed during a suction stroke, while the inlet valve is open. As the piston advances from the TDC to the BDC, a partial vacuum is created inside the cylinder, drawing in atmospheric air.

Compression Stroke:

The piston travels from BDC to TDC during this stroke. The outcome is a compression and heating of the air inside the cylinder.

Both of the valves are closed during this stroke. The air's temperature is approximately 800°C. The cylinder ignites internally when the fuel injector injects high-pressure fuel into compressed hot air after the compression stroke.

Power or Expansion Stroke:

Both of the valves are closed during this stroke. The expansion of burnt gas pushes the piston down at TDC. Consequently, a Power stroke is generated.

Exhaust stroke:

The inlet valve is closed during this stroke, and the exhaust valve is open. The piston forces the burnt gas out of the cylinder as it moves from BDC to TDC. Additionally, the charred gas is entirely removed in this instance by the scavenging process.

Valve-timing diagram for four-stroke Diesel engine:

- Inlet valve open at 10°-30° before TDC

- The Inlet valve closes at 20°-50° after BDC

- The exhaust valve opens approximately 40° before BDC

- The exhaust valve closes 15° after TDC

- Fuel injection starts 5°-15° before TDC

- Fuel injection stops 15°-25° after TDC

Advantages and Disadvantages of 4 Stroke Engine

Research on 4 stroke engines, commonly gasoline engines, has been ongoing for many years. Most cars, light trucks, medium-to-large motorcycles, and lawnmowers still run on these Internal Combustion Engines (ICE). An internal combustion engine that requires four strokes to complete a power cycle is called a four-stroke engine. Since four-stroke engines are still in use today, there are benefits and drawbacks to consider.

Journey of 4 Stroke Engines

In 1876, the first four-stroke gasoline-powered engine was constructed in Germany. The first automobiles with this engine type produced for commercial use were made by Carl Benz in 1886. Later, every automaker started producing automobiles and vehicles that could reach up to 127 miles per hour.

Cars with this type of engine are closely examined for various reasons. These engines are straightforward, have fast acceleration, produce minimal pollution, are cost-effective, and are powerful. The development of electric and hybrid cars, including those powered by hydrogen, results from numerous reasons.

What are the Advantages of the four-stroke engine?

Four-stroke gasoline or diesel engines power almost all modern vehicles, making them a significant technological advancement. Even while the popularity of electric bikes and cars is growing, the technology still needs to be improved to create powerful, high-speed vehicles that can carry large loads. This type of I.C. engine has many advantages over 2 stroke engines, so it is widely used. These are a few benefits of a four-stroke engine.

Higher Torque

When the same amount of gasoline is supplied, the engine produces more torque than conventional engines. An automobile can operate more powerfully and smoothly with more torque. The strong torque can make vehicles with less noise and vibration faster.

Longer Life

The improved cooling and lubricating systems of the 4 stroke engine result in a longer engine life. It lessens the wear and tear of the engine cylinder and its parts, which is relatively more so in other versions. They are also more stable at incredible speeds and power operations due to the improved damping.

Fuel efficiency is one of the advantages of a 4 Stroke Engine.

The valves enable the fuel losses, and the intake and exhaust are managed more efficiently. These engines operate solely on time intake of gasoline during the four-cycle operation; unlike two-stroke engines, they do not have scavenging.

Less polluting

Only combustion may use the fresh charge since the exhaust is better regulated. This makes this engine a better choice in terms of its environmental effects. The 2 stroke and steam engines, among other conventional vehicles, produce more pollution than the 4 stroke engine.

Separate Lubrication

Lubricant oil does not need to be added to the fuel for cooling or lubrication. It is more cost-effective since it lowers the price of oil, and other lubrication methods work better at protecting the internal components from frictional damage. Better design and technology also minimize power losses.

What are the Disadvantages of 4 stroke engine?

Despite the world's heavy reliance on 4 stroke engines, technological developments will eventually result in improved automobiles. It may be feasible to see flying engines and cars requiring a more sophisticated internal power generation system. The two primary drawbacks of four-stroke engines are their restricted fuel supply and the global growth in pollution caused by automobiles. These are reasons why 4-stroke engines require innovation and might become obsolete shortly.

Less Power

A 4 stroke engine produces half as much power as a 2 stroke engine. This kind of engine requires more strokes to accomplish a single spin. Compared to its simpler version, this renders them a less potent engine.

Complicated Construction

The sheer quantity of components and different inputs (cooling, lubrication, valves, etc.) make designing extremely difficult and even more challenging to build. A four-stroke engine can have a total failure or its efficiency and working life reduced by a slight variation or flaw.

More Expensive

It is more expensive than simpler designs since there are more pieces involved. The expense and effort involved in creating and producing these vehicles with this technology raises the total cost of ownership. The disadvantage of a four-stroke engine is that it costs more than a two-stroke car, even with the same overall design.

Costlier fuels

As long as the engines are operating, the primary power sources for the machines are gasoline and diesel. Let's also accept that non-renewable energy sources like petroleum will eventually run out on Earth. Gasoline and diesel are costly resources due to their transportation and refinement, which also raises the cost of vehicle transportation. The rising cost of petroleum indirectly impacts the nation's economy and increases inflation.

Regular maintenance is one of the leading disadvantages of 4 Stroke Engine.

These I.C. engines require routine upkeep and servicing for their installed vehicles. This also increases the consumer's financial burden. The expense of operating and maintaining vehicles is on the rise, potentially rendering them unusable and driving up the cost of goods and services.

Conclusion on Pros and Cons of 4 Stroke Engine

Almost everyone uses 4 stroke gasoline or diesel engines for private or public transportation. These capabilities also enable sending everyday necessities from different regions of the nation to your doorstep.

It's important to consider both the positive and negative aspects of four-stroke engines. Understanding their benefits can be challenging. However, we need additional resources to meet the world's energy needs in the future and lessen environmental harm.

What Is the Difference Between a 2-stroke and a 4-stroke Engine?

A four-stroke engine requires four steps, or two full revolutions, to complete a single power stroke, whereas a two-stroke engine requires two stages, or one full revolution, to accomplish the same task. This is the primary distinction between the two types of engines. It implies that a two-stroke engine may be able to weigh less and generate twice as much power as a four-stroke engine.

4-Stroke Engine

Four-stroke engines are fuel-efficient and operate in four steps:

- Intake: Fuel is pulled in with a downward stroke when the intake valve is open.

- Compression: As the piston moves upward, the fuel is compressed.

- Power: The engine's power is generated by igniting the compressed gasoline.

- Exhaust: The exhaust gasses leave the cylinder when the exhaust valve opens.

2-Stroke Engine

The upstroke of a two-stroke engine includes the steps of compression and ignition, whereas the downstroke combines the steps of power and exhaust. Although this method produces less torque, it has fewer moving parts, making maintenance simpler.

The two-step process includes:

- Upstroke (ignition/compression): Fuel and air enter the crankcase when the piston rises. Compression and ignition are applied to the fuel-air mixture.

- Downstroke (power/exhaust): The piston is forced downward and the exhaust is released after the fuel ignites.

Both engine types have their pros and cons, and the one that will work best for you depends on the needs of your application.

2-Stroke vs. 4-Stroke Engines

The primary distinction between two- and four-stroke engines is how they function. The combustion cycle is how both engines generate power.

A 4-stroke engine completes one power stroke by going through four phases, or two full revolutions, which is the primary distinction between a 2-stroke and a 4-stroke engine. One power stroke of a two-stroke engine requires two phases, or one full revolution.

When an engine is in the combustion cycle, the piston travels up and down inside a cylinder. When the piston travels from the top center to the bottom of the cylinder, it is called a stroke. The piston collects gas and air as it travels down the cylinder during a combustion cycle. The exhaust valve opens to release the exhaust when the piston rises back to the top.

A new mixture of air, fuel, and oil is drawn in the hermetically closed crankcase beneath the piston as it moves higher, compressing the air, fuel, and oil mixture in the combustion chamber. This is how two-stroke engines operate.

One of the most popular types of internal combustion engines is the 4-stroke. Each power cycle is accomplished by pistons going through four events, or up and down piston motions. The cycle is finished and prepared to start over after the four events are finished.

Although both engines have a fairly similar combustion cycle, the number of strokes the piston must make to finish the process varies.The five stages of the combustion cycle—intake, compression, ignition, combustion, and exhaust—are finished in two piston strokes by a two-stroke engine. In contrast, a four-stroke engine requires four piston strokes to finish a combustion cycle. Two crankshaft rotations for a four-stroke engine and one crankshaft revolution for a two-stroke engine are alternate ways to conceptualize this procedure.

Which Engine Is Better?

The choice of whether a two-stroke or four-stroke engine is superior depends only on your individual preferences and applications; there is no one correct answer. Two-stroke engines are lighter and faster than four-stroke engines, but four-stroke engines are more efficient and often last longer. Although a 4-stroke engine uses less gasoline, a 2-stroke engine has more power.

It's also critical to comprehend the lubrication requirements of each engine type before choosing one. An oil and gasoline combination is needed for a two-stroke engine. The fuel ignites while the engine is running and continuously consumes the oil. Oil in the gasoline is not necessary for four-stroke motors. The four-stroke engine is therefore a more fuel-efficient choice. After lubricating the various engine components, the oil in a four-stroke engine returns to the crankcase.

Distributing oil to the moving parts is the lubrication system's responsibility in order to lessen friction between surfaces that come into contact with one another. In addition to harming moving parts, friction also reduces engine efficiency. Decreased efficiency results in more pollutants, lower engine life, lower horsepower and torque, and higher maintenance expenses.

In the end, being aware of the differences between two-stroke and four-stroke engines and their requirements will enable you to make the best decision and take preventative maintenance measures during the course of your engine's life.

Frequently Asked Questions

What is the advantage of a 4 stroke engine?

Both professional and leisure users like 4 stroke engines. Compared to 2 stroke engines, they feature a decent mix of power, reliability, and efficiency. Four strokes mechanically divide each event, lowering unburned fuel emissions in terms of carbon monoxide. Additionally, it separates gasoline from oil, reducing emissions of carbon monoxide.

What is the difference between a 2 stroke and a 4 stroke engine?

That's the primary way a 4 stroke engine differs from a 2 stroke engine. As opposed to the latter, which only travels through two phases or one revolution to complete a power stroke, the former goes through four or two complete revolutions.

What fuel do I use in a 4 stroke engine?

Most lawnmowers use 4 stroke engines. Premium unleaded gasoline with an octane level of 87 or above is needed for these. You could use ethanol, which contains gas. It should not, however, have more than 10% ethanol by weight.

Do you mix oil and gas in a 4 stroke engine?

Oil and gas need to be mixed in the right amounts for two-stroke engines to lubricate the crankcase properly. Engines with four strokes, however, use gas and oil separately.